Business Benefits of Professional MEP Engineering Services

Building design is often viewed simply as a requirement for construction, and an expense that cannot be avoided. However, the design process provides a great opportunity to achieve long-term benefits. Smart design decisions can enhance the functions of building systems, while cutting down their operation and maintenance costs.

When building systems are designed by qualified MEP engineers, performance is enhanced and costs are optimized. For this reason, engineering can be considered an investment: it has a cost like a any professional service, but the benefits achieved are much greater.

For instance, MEP engineers can suggest energy efficiency measures to reduce the running cost of building systems. In the case of a large building, these measures can save millions of dollars over the service life of the property.

There are many aspects of building systems that can be optimized during the design process:

-

Equipment selection: Higher performance is achieved when equipment is adequate for the intended application, and of the right capacity.

-

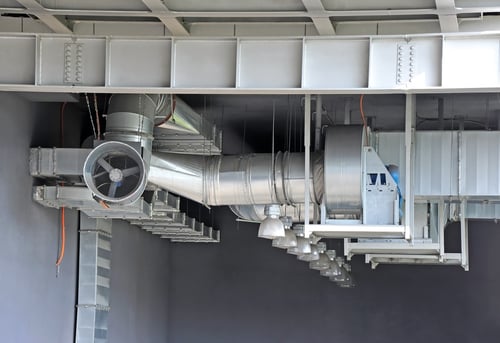

Mechanical, electrical and plumbing layout: A smart layout reduces the total length of conduit, piping and ductwork. The installation can be completed with less materials and for a lower cost.

-

Simplified maintenance: Professional MEP engineers consider maintenance during the design process, making sure the installation is easy to access and service. Adequate equipment selection leads to a longer service life, reduced noise and vibration issues, and less frequent part replacements.

Optimize MEP installation costs and boost performance.

Benefits of Having the Right Equipment

“Rules of thumb” are tempting when selecting equipment, since they give quick answers. Unfortunately, these answers are also inaccurate. Instead of these quick calculations, MEP engineers recommend a careful assessment of project needs, to then suggest the most suitable equipment for each task. Heating and cooling systems normally have the largest equipment pieces in a building, and a correct specification brings several benefits:

-

Equipment costs decrease along with rated capacity. Rules of thumb often lead to oversized equipment and unnecessary expenses, while an adequate design process optimizes capacity and cost. Oversized equipment also consumes more water and energy than necessary, increasing utility bills.

-

Poorly selected equipment is susceptible to breakdowns and requires more maintenance, for the simple reason that it is being used incorrectly. The best way to solve these maintenance problems is by never allowing them to happen in the first place.

Optimizing the Layout of Building Systems

Building system layouts are easy to overlook, since individual components do not appear expensive. For example, ½ in. x 10 ft. EMT conduit can be purchased for less than $5 each, and some fittings cost less than $1. With prices like these, it doesn’t seem that these components add significant expenses to the overall project budget.

However, consider that ductwork, plumbing lines and electrical circuits are thousands of feet long in large buildings. When the total material costs are calculated, and added with the labor cost, these distribution systems can become very expensive.

When MEP installations are well designed, full building coverage is achieved with the lowest possible length of conduit, piping and ducts. More compact building systems also improve energy efficiency - consider the following examples:

-

Longer air ducts need larger fans, which consume more power.

-

Longer plumbing lines need more pumping power to overcome piping losses.

-

Longer electrical circuits lose more power in the form of dissipated heat, while causing a higher voltage drop between the source and the load.

Complex layouts can be difficult to optimize with conventional 2D design software. However, modern software allows the creation of 3D models, where location conflicts are detected and signaled automatically. MEP engineers can use these powerful tools to optimize the layout of building systems.

How Effective MEP Engineering Simplifies Maintenance

Maintenance activities can only be performed effectively when system components are accessible, and this is determined during the design process. MEP engineers must make sure that no equipment and components are left in places that are difficult or impossible to access once the building is operating.

Of course, an effective MEP design minimizes the need for maintenance in the first place. The following are some ways to achieve this:

-

Specifying components with a long service life. For example, there are LED lamps that last over 50,000 hours, while most fluorescent lamps last less than 20,000 h, and most incandescent lighting rated for less than 2,000 h.

-

Specifying adequate equipment supports to minimize vibration. This minimizes noise and mechanical wear, reducing the frequency of part replacements.

-

Adequate equipment capacity. Undersized equipment is prone to frequent breakdowns because its capacity is exceeded. However, oversized equipment also suffers from maintenance issues because it tends to run in shorter cycles - frequent starts and stops cause faster deterioration.

The design documents themselves are also valuable as maintenance tools. When a MEP installation is completed with clear drawings, a digital 3D model and ample documentation, the building’s maintenance staff can easily pinpoint issues and solve them.

Involving MEP engineers early in the design process leads to considerable savings in the long run. Design engineers can help you reduce the installed cost of building systems, while suggesting measures that reduce operation and maintenance expenses in the long run.

Anuj Srivastava

Anuj Srivastava is a principal partner at NY Engineers. He is known for his MEP franchise market knowledge. Anuj is currently leading a team of 100+ MEP/FP engineers and has successfully led over 1500 franchise projects in the US.

Join 15,000+ Fellow Architects and Contractors

Get expert engineering tips straight to your inbox. Subscribe to the NY Engineers Blog below.