Saving Electricity with a Transformer Upgrade

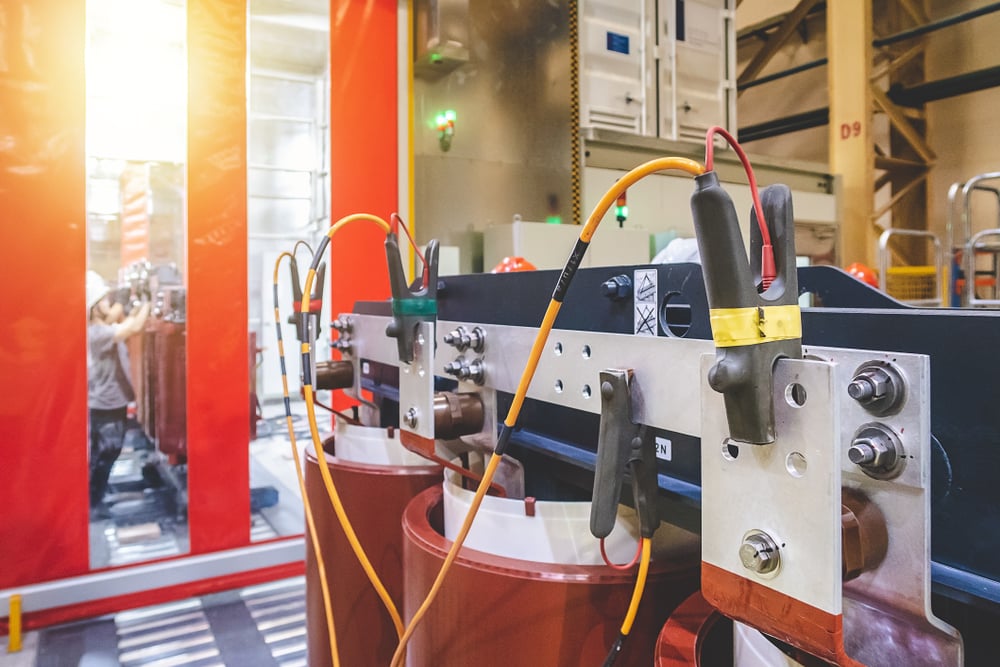

Transformers are fundamental for electricity distribution, stepping the voltage up and down as it travels from power plants to individual buildings. Transformers are among the most efficient electrical devices, with a typical efficiency rating above 97%. However, consider that transformers are always operational, even when the load connected to them is small. For this reason, even a minor gain in transformer efficiency can save thousands of dollars over time.

The latest transformer efficiency standards from the US Department of Energy came into effect since January 2016. These standards do not force building owners to upgrade their transformers, but all units manufactured since then must meet the minimum efficiency values in the standard. The specific transformer types covered are the following:

- Low-voltage dry-type transformers

- Medium-voltage dry-type transformers

- Liquid-filled distribution transformers

The efficiency changes for low-voltage dry-type (LVDT) transformers are the most relevant for building owners, since these are the units normally found indoors. The other two types are used to step down distribution voltages like 34,500 V, which are only found at the main service connection.

Reduce the power consumption of your building.

If your building has old transformers, upgrading them to newer models can be a promising energy efficiency measure. Even greater savings are possible if you measure the total harmonic distortion (THD) of your electrical system, and add the corresponding filters. Transformers become less efficient when their loads have a high harmonic content.

DOE 2016 Efficiency Levels for LVDT Transformers

LVDT transformers are very common in facilities that handle different voltage levels, such as 480/277 V and 220/127 V. With the DOE 2016 standard, the minimum efficiency for three-phase models was increased. The efficiency of single-phase models remains the same, but is now be specified with two decimals (the previous standard only used one decimal).

Efficiency Requirements for Single-Phase, Dry-Type, Low-Voltage Transformers

|

Capacity (kVA) |

TP-1 Efficiency (Previous) |

DOE 2016 Efficiency |

|

15 25 37.5 50 75 100 167 250 333 |

97.7% 98.0% 98.2% 98.3% 98.5% 98.6% 98.7% 98.8% 98.9% |

97.70% 98.00% 98.20% 98.30% 98.50% 98.60% 98.70% 98.80% 98.90% |

Efficiency Requirements for Three-Phase, Dry-Type, Low-Voltage Transformers

|

Capacity (kVA) |

TP-1 Efficiency (Previous) |

DOE 2016 Efficiency |

|

15 30 45 75 112.5 150 225 300 500 750 1000 |

97.0% 97.5% 97.7% 98.0% 98.2% 98.3% 98.5% 98.6% 98.7% 98.8% 98.9% |

97.89% 98.23% 98.40% 98.60% 98.74% 98.83% 98.94% 99.02% 99.14% 99.23% 99.28% |

If your have single-phase transformers that meet the previous standard (TP-1), upgrading to DOE 2016 efficiency units will save little or no energy. However, significant savings are possible when upgrading three-phase transformers, especially in buildings with many of them.

Energy Savings of a Transformer Upgrade: An Example

The efficiency gains for three-phase dry-type transformers may seem small, but savings are high when you consider continuous operation. Consider the following example:

- A 150 kVA transformer is upgraded from TP-1 to DOE 2016 efficiency.

- The transformer operates continuously - 8760 hours per year.

- The local electricity price is 15 cents/kWh.

The existing unit has a TP-1 efficiency of 98.3% with a 1.7% loss (2,550W). However, the more efficient unit has an efficiency of 98.83%, with a 1.17% (1,755W). The upgrade reduces the power loss by 795W, which results in annual energy savings of 6,964 kWh. With an electricity price of 15 cents/kWh, the upgrade saves $1,045 per year. Assuming a transformer price of $5,500, the payback period is slightly over five years.

This example considers an existing transformer that meets the previous TP-1 efficiency level. When upgrading older and less efficient units, the savings are higher and the payback period is shorter.

In a facility with many LVDT transformers, a wide variety of kVA ratings and efficiency levels can be expected. With a professional energy audit, you can identify the most promising upgrades to give them priority.

Consider that other energy efficiency measures can reduce the load on transformers. For example, if 200 HID lamps that consume 450W each are upgraded to 150W LED fixtures, the total power consumption will drop by 60 kW. If this lighting system has a dedicated transformer that is already old, the replacement can have a higher efficiency and a lower kVA rating.

Michael Tobias

Michael Tobias, the Founding Principal of NY Engineers, currently leads a team of 50+ MEP/FP engineers and has led over 1,000 projects in the US

Join 15,000+ Fellow Architects and Contractors

Get expert engineering tips straight to your inbox. Subscribe to the NY Engineers Blog below.