Mechanical COMcheck

5 Days- That's a Lightning Fast Turnaround Time!

1

Upload Files and Pay

Upload PDF or CAD files, and pay to start the process. An engineer is auto-assigned to your project.

2

Document Review

An engineer will review all the documents shared and connect with you if anything else is required. Initial work starts.

3

Work Starts

Actual design/ report creation work begins.

4

Quality Check

The design and report are checked by the project manager to make sure 100% quality work is delivered.

5

Delivery

The design/ report is delivered to you.

NEED HELP OR ADDITIONALINFORMATION?

C A L L U S N O W

(646) 776-4010Get Your Mechanical COMcheck Report In 3 Easy Steps

0%

Get the lighting COMcheck compliance report within

5 Days

Accurate calculation of energy consumption

0 Errors

Match standerds of ASHRAE, state and IMC codes

Code Compliant

Improve building energy efficiency

Save Cost

$ 750

Mechanical COMcheck

Documents Required

Photographs/ cut sheets, and design drawings of HVAC and plumbing equipment.

Delivery Time & Standards

We deliver your report (digitally) within 5 business days as per ASHRAE/IMC.

What's not Covered

This service does not cover site visits, stamping, DOB/DEP filing, and more than 2 minor iterations.

Service Constraint

The service fee is limited to per building up to 6 floors.

$750*

Mechanical COMcheck

Get the Mechanical COMcheck compliance report at lightning speed.

Accurate calculation of energy consumption.

Match standards of ASHRAE, state and IMC codes.

Improve building energy efficiency.

Get Your Mechanical COMcheck Report From Professionals

Maximize Energy Efficiency

Mechanical COMcheck enables us to maximize cost-effective energy efficiency at whichever level of priority is required by the building owner and/or relevant energy codes. It is invaluable when specifying heating and cooling equipment.

Designs Developed Using COMcheck

COMcheck may be used to generate a checklist of energy requirements that must be met during the design stages of buildings. While not mandatory, it is an invaluable tool that is accepted by state and local authorities.

Building Energy Code Compliance

COMcheck simplifies complex legislation. It was developed for the U.S. Department of Energy (DOE) in 1997 to make it easy for designers and builders to comply with residential high-rise and commercial building energy codes.

Our on-demand engineering expert

Still not sure about how to proceed?

YOU CAN WRITE TO ME AT inquiry@ny-engineers.com

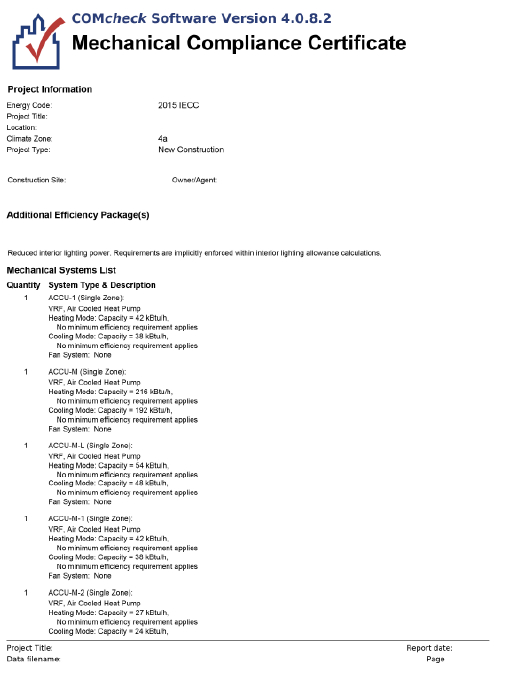

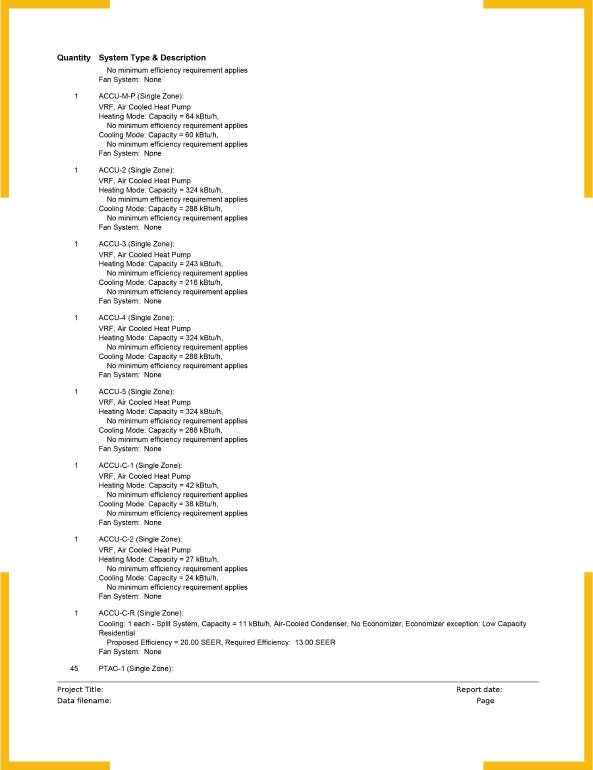

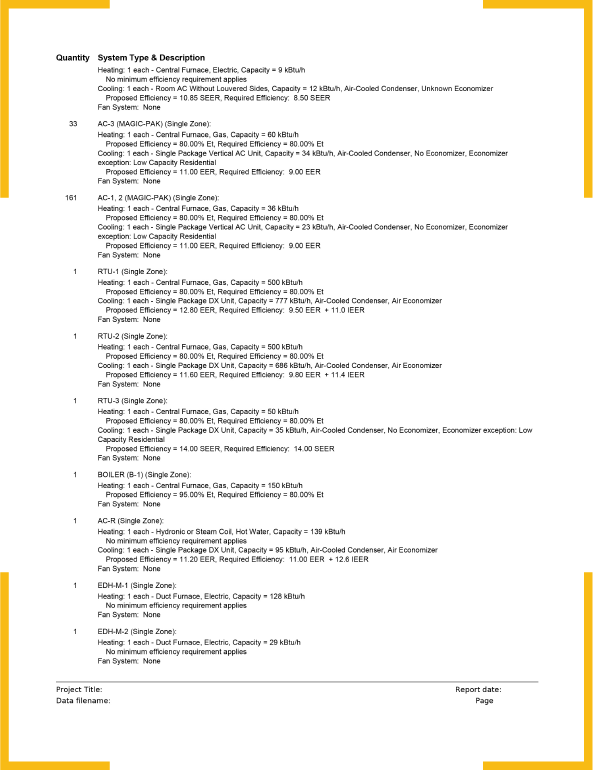

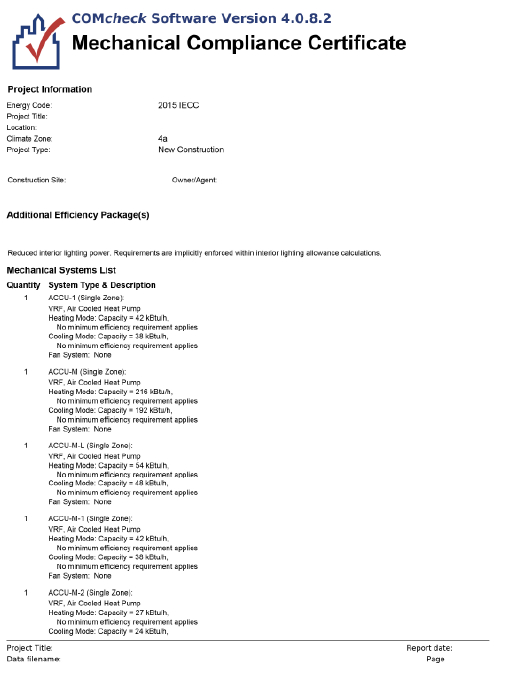

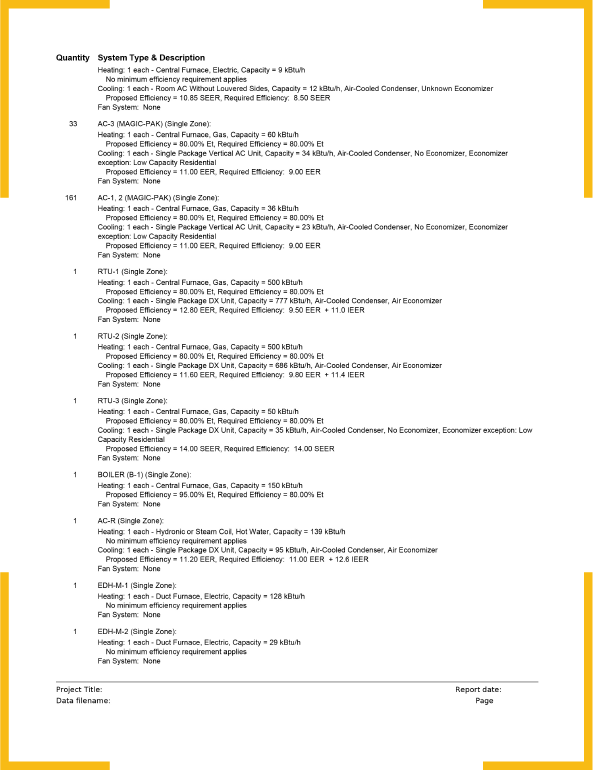

COMcheck is software that enables us to demonstrate compliance with high-rise (over three stories) residential and commercial building energy codes and standards. Whether NY Engineers is designing the heating, cooling, and hot water systems in your building, or you simply need your designs checked for compliance, COMcheck is the highly efficient, failsafe tool that we use.

While COMcheck is designed to check compliance with the building envelope, lighting, and mechanical documentation requirements for building design, the mechanical section of COMcheck works differently. So, instead of generating a numeric index, which it does for the building envelope and lighting, it generates a list of mandatory requirements for mechanical components that are based on the components supplied by the user.

It is important to realize that most of the mechanical requirements of energy codes, including the IECC, ASHRAE Standard 90.1 and the various U.S. state codes, are mandatory. But if buildings comply with the mechanical section of COMcheck, they are considered (or deemed to) meet the requirements of the various codes and standards. That is why you need Mechanical COMcheck!

The mechanical engineering team at NY Engineers has extensive experience designing all the elements of heating, ventilation, and air conditioning (HVAC) as well as water heating systems in commercial and high-rise residential buildings. We can also provide the guidance required to ensure that the codes relevant to your city are complied with.

But we don’t just rely on our knowledge and experience, we use COMcheck to make 100% certain that designs are code compliant. That’s why you can rely on NY Engineers.

Various energy codes provide minimum criteria for the size and efficiency of HVAC equipment and systems, taking account of the energy demands of building space.

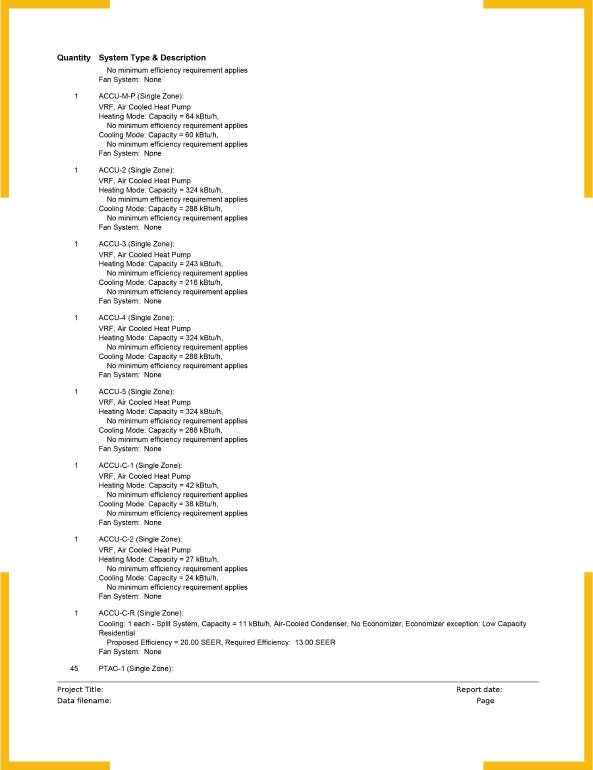

COMcheck covers every type of mechanical equipment and mechanical components that have mandatory requirements in terms of the various standards and codes that apply to the United States.

The scope of permitted equipment types for building cooling and heating includes:

- Heat pumps, all central air handling units, heating and cooling sources, and zonal fan distribution systems.

- Plant equipment that is supported by:

- Fuel-fired steam, electric, and hot-water boilers

- Electric and absorption water chillers

- Refrigeration condensing units

- A variety of different single-zone and multi-zone systems including:

- Constant-volume single-zone distribution systems

- Variable volume changeover multiple-zone distribution systems

- Radiant heating systems

- Single-duct variable air volume systems with standard or fan-powered zone terminal devices, with or without reheat

- Dual-duct variable air volume systems with mixing, standard VAV, or fan-powered VAV boxes installed as zone-terminal devices

- Three-duct constant volume systems with zone-terminal mixing boxes

If newly-purchased heating and cooling equipment is included, their efficiency does not have to be checked.

The use of economizers, which are mechanical devices installed to reduce energy consumption, is required by ASHRAE Standard 90.1 in specified climatic regions with systems that have a cooling capacity of more than 90,000 Btu/h. Because efficiency benefits and cost-effectiveness can vary significantly depending on the climate, COMcheck has an economizer trade-off that enables building designers to use higher-efficiency air-conditioning equipment instead of an economizer.

Even though the trade-off is not specified in Standard 90.1, it was developed from data, in the form of tables, that are incorporated in the standard.

COMcheck provides energy efficiency ratio (EER) requirements for the economizer trade-off, indicating what increased cooling efficiency is required for a heat pump or air-conditioning unit to offset the absence of an air-side economizer in the climate zones where economizers are required. Depending on the equipment category size and zone the building is in, there will either be a 17% or 28% increase (or improvement) in the EER.

The trade-off is acceptable in most situations because it usually results in energy savings that are greater than the standard requires. However, it is not permitted for built-up systems because the supporting research for the trade-off applies specifically to unitary packaged equipment.

Load calculations are an essential element of all good mechanical design. Mechanical engineers use them when they select equipment to ensure that even when using the most economical items, comfort conditions will be maintained.

However, it is impossible to regulate the quality of assumptions made by designers or their judgment undertaking load calculations. The problem is that there are numerous variations on assumptions used when doing load calculations including the climate and future additions, as well as the designer’s experience.

Building inspectors don’t normally review load calculations for accuracy, which makes this a primary responsibility of the designer.

A similar scenario applies to equipment and system sizing, which, like load calculations is a vital element of good mechanical design. In addition to the availability and cost of equipment, there are a number of parameters that designers must consider, including sensible and latent loads, duct design, airflow, operating warm-up and cool-down sequences, and the location where equipment will be installed. While Standard 90.1 does take various parameters into account, in reality, there are so many possibilities, their requirements don’t have any practical effect on energy consumption.

Sizing requirements, like load calculations, aren’t explicitly enforced by building departments and local authorities. However, engineers have a legal responsibility to size and specify system equipment properly. Ultimately, the requirement is for systems and equipment to be specified correctly on the plans, and then, if necessary, a field inspector can do on-site inspections to ensure the system has been built in accordance with the approved plans.

If people are expected to remain in enclosed spaces for extended periods of time it is essential that these spaces are continuously vented with outdoor air. COMcheck refers to local codes for minimum ventilation requirements or to the International Mechanical Code (IMC).

When it comes to fan systems, COMcheck requires that they are operated continuously (when the space or room is occupied) to meet the provisions of the IMC. Additionally, a thermostat capable of being set to run continuously must be used, and systems must be capable of reducing the outdoor airflow to minimum levels using control dampers or fan volume controls either manually or automatically.

Another important element that COMcheck covers is the use of natural ventilation through windows, doors, louvers, and so on to ensure compliance. But users of the software are referred to local codes and the IMC for acceptable minimum opening areas that will ensure there are adequate natural ventilation rates.

The IMC allows natural ventilation to be used instead of continuous mechanical ventilation and it contains provisions that must be met if ventilation is provided via non-mechanical means. The IMC takes human response into account and allows occupants to ventilate spaces by opening windows and so on if they want to allow outdoor air into rooms. Acknowledging that they have the ability to control this type of ventilation, the IMC doesn’t expect it to be a permanent form of ventilation (in other words it doesn’t have to remain open all the time.)

While COMcheck does place limits on air handler design in variable flow systems, there are no limits on fan power in terms of W/cfm, which is how the efficacy of fans is measured. But this is simply because it was felt that the Standard 90.1 required couldn’t be enforced. Nevertheless, system designs that use the type of HVAC equipment allowed by COMcheck typically use less fan energy than the maximum allowed by Standard 90.1.

In terms of fan control technologies, COMcheck requires more efficient fan airflows that start at 25 hp rather than 75 hp required by the 90.1 code.

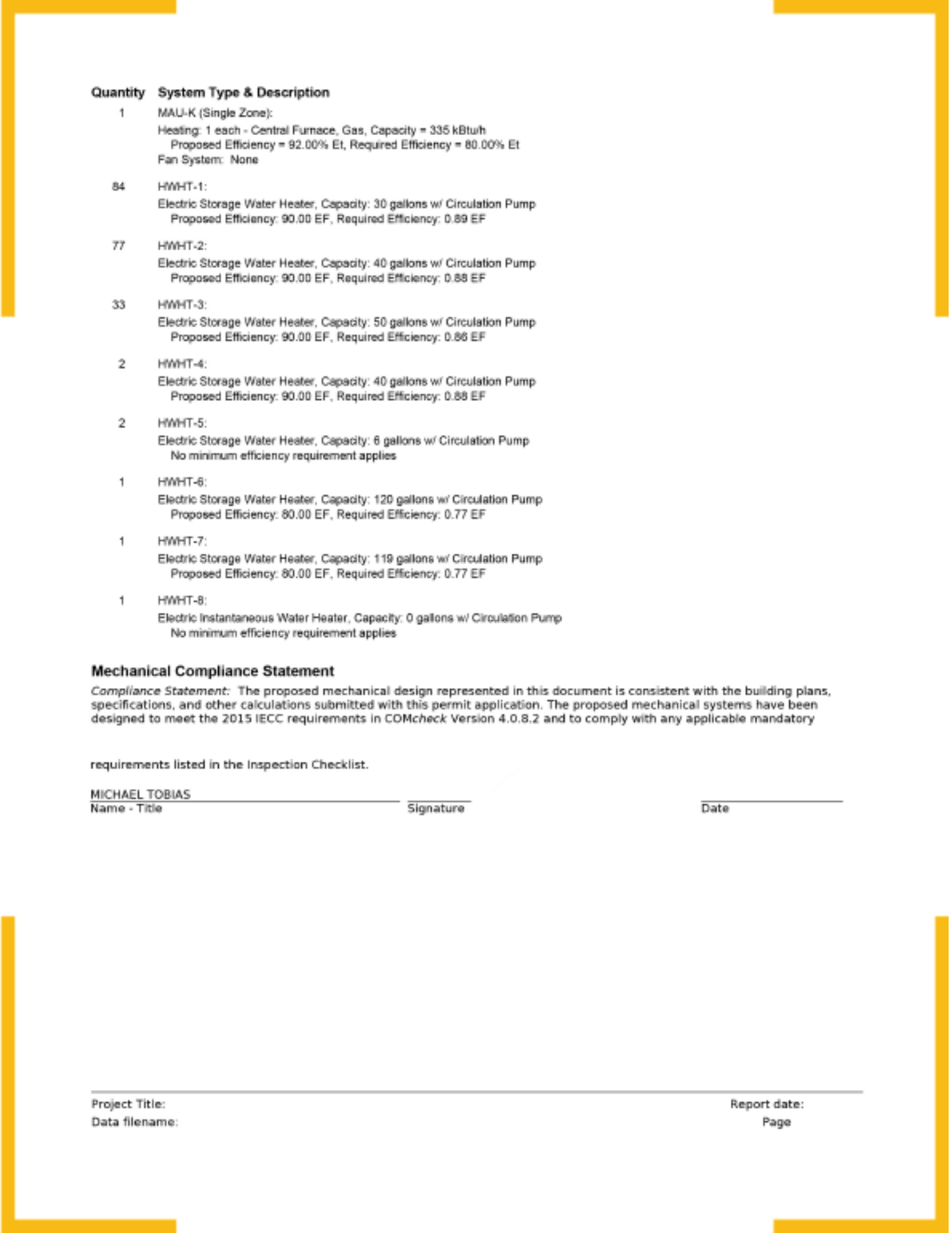

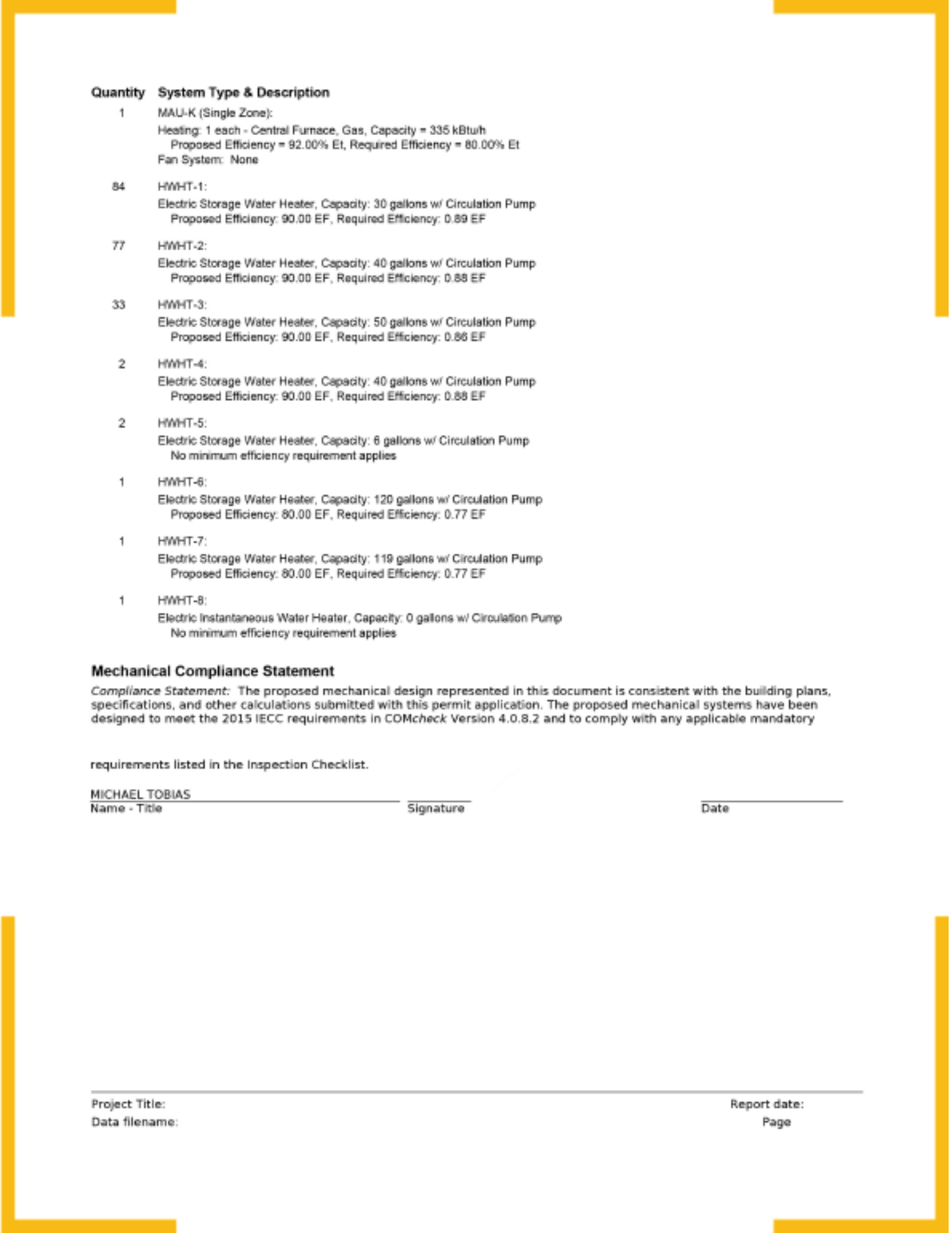

Energy codes provide minimum criteria to effectively heat and deliver hot water, as well as insulate circulating hot water systems, service water heating equipment performance efficiencies in commercial applications, heat traps, controls, and pool heaters.

However, COMcheck only covers water-heating equipment that is included in Federal efficiency regulations, primarily the Energy Policy Act, Public Law 102-486. Also, the water-heating equipment efficiency levels that are equivalent to those in Standard 90.1 are mandated as an EP Act manufacturing standard. This means that all types of water-heating covered will comply with efficiency levels in the 90.1 code.

Water-heating equipment that is covered includes:

- All types of electric water heaters

- Fuel-fired:

- Storage water heaters

- Packaged boilers that are used as water heaters

- Instantaneous heaters, which, in terms of the EP Act means a water heater that has an input rating of at least 4,000 Btu/h per gallon of water stored

- Pool and spa heaters

Other equipment and issues that are addressed through the EP Act Public Law legislation include:

- The efficiency of service water heating and minimum manufacturing standards for equipment efficiencies

- Electric and oil service water heating standby losses

- Unfired storage tanks

- Storage volume

Gas and oil waters heaters with a storage volume greater than 140 gallons are not covered by Federal efficiency regulations and their use is only permitted under the Complex Systems section, not the Simple Systems section.

In terms of piping insulation, both Standard 90.1 and COMcheck have requirements for vent or flue dampers on water heaters, though this is waived if there is no electrical supply, as well as for heat traps on non-circulating water-heating systems.

Requirements for hot-water temperature settings were incorporated in Mechanical COMcheck, but because they were extremely difficult to enforce, they were removed. However, the Standard 90.1 requirement for automatic time-switch controls on circulating hot-water systems has been maintained in COMcheck. There is also a COMcheck requirement for time-switch controls if heat tracer tape is used with circulating systems. This is intended to prevent the use of circulating water to prevent freezing when heat tracing is provided for.

COMcheck maintains the requirement for swimming pools to have shutoff controls that are readily accessible, as well as time-clock switches for their heaters and pumps. There are though exceptions to the time-clock rule for site-recovered or solar heating, in keeping with Standard 90.1. The Standard 90.1 exception for pools with more than 70% of the annual energy for heat supplied from site-solar or site-recovered systems, which requires a compliance officer to certify the annual fraction of heating energy from different sources, is no longer included in COMcheck. The result is that the COMcheck requirement is both more restrictive and more easily enforceable.

Perhaps surprisingly, water conservation requirements are not included in COMcheck. However, the EP Act Public Law legislation addresses appliances that use water, so it is assumed that all new toilets and showerheads will meet this manufacturing standard.

As discussed earlier, COMcheck supports various codes and standards, including the IECC, so from time-to-time changes are made to the software to ensure it complies with the international energy and other codes that are constantly updated.

This is why NY Engineers uses the most up-to-date version of COMcheck, which is updated every three years, most recently in November 2018.

There is absolutely no doubt that it is one of the best ways to ensure that mechanical engineering designs are compliant.

What Is Mechanical COMcheck and Why Do You Need It?

COMcheck is software that enables us to demonstrate compliance with high-rise (over three stories) residential and commercial building energy codes and standards. Whether NY Engineers is designing the heating, cooling, and hot water systems in your building, or you simply need your designs checked for compliance, COMcheck is the highly efficient, failsafe tool that we use.

While COMcheck is designed to check compliance with the building envelope, lighting, and mechanical documentation requirements for building design, the mechanical section of COMcheck works differently. So, instead of generating a numeric index, which it does for the building envelope and lighting, it generates a list of mandatory requirements for mechanical components that are based on the components supplied by the user.

It is important to realize that most of the mechanical requirements of energy codes, including the IECC, ASHRAE Standard 90.1 and the various U.S. state codes, are mandatory. But if buildings comply with the mechanical section of COMcheck, they are considered (or deemed to) meet the requirements of the various codes and standards. That is why you need Mechanical COMcheck!

The Professionals at NY Engineers Understand Mechanical Energy Requirements

The mechanical engineering team at NY Engineers has extensive experience designing all the elements of heating, ventilation, and air conditioning (HVAC) as well as water heating systems in commercial and high-rise residential buildings. We can also provide the guidance required to ensure that the codes relevant to your city are complied with.

But we don’t just rely on our knowledge and experience, we use COMcheck to make 100% certain that designs are code compliant. That’s why you can rely on NY Engineers.

Scope and Permitted Types of Heating & Cooling Equipment

Various energy codes provide minimum criteria for the size and efficiency of HVAC equipment and systems, taking account of the energy demands of building space.

COMcheck covers every type of mechanical equipment and mechanical components that have mandatory requirements in terms of the various standards and codes that apply to the United States.

The scope of permitted equipment types for building cooling and heating includes:

- Heat pumps, all central air handling units, heating and cooling sources, and zonal fan distribution systems.

- Plant equipment that is supported by:

- Fuel-fired steam, electric, and hot-water boilers

- Electric and absorption water chillers

- Refrigeration condensing units

- A variety of different single-zone and multi-zone systems including:

- Constant-volume single-zone distribution systems

- Variable volume changeover multiple-zone distribution systems

- Radiant heating systems

- Single-duct variable air volume systems with standard or fan-powered zone terminal devices, with or without reheat

- Dual-duct variable air volume systems with mixing, standard VAV, or fan-powered VAV boxes installed as zone-terminal devices

- Three-duct constant volume systems with zone-terminal mixing boxes

If newly-purchased heating and cooling equipment is included, their efficiency does not have to be checked.

Economizer Trade-off

The use of economizers, which are mechanical devices installed to reduce energy consumption, is required by ASHRAE Standard 90.1 in specified climatic regions with systems that have a cooling capacity of more than 90,000 Btu/h. Because efficiency benefits and cost-effectiveness can vary significantly depending on the climate, COMcheck has an economizer trade-off that enables building designers to use higher-efficiency air-conditioning equipment instead of an economizer.

Even though the trade-off is not specified in Standard 90.1, it was developed from data, in the form of tables, that are incorporated in the standard.

COMcheck provides energy efficiency ratio (EER) requirements for the economizer trade-off, indicating what increased cooling efficiency is required for a heat pump or air-conditioning unit to offset the absence of an air-side economizer in the climate zones where economizers are required. Depending on the equipment category size and zone the building is in, there will either be a 17% or 28% increase (or improvement) in the EER.

The trade-off is acceptable in most situations because it usually results in energy savings that are greater than the standard requires. However, it is not permitted for built-up systems because the supporting research for the trade-off applies specifically to unitary packaged equipment.

Load Calculations & Equipment Sizing

Load calculations are an essential element of all good mechanical design. Mechanical engineers use them when they select equipment to ensure that even when using the most economical items, comfort conditions will be maintained.

However, it is impossible to regulate the quality of assumptions made by designers or their judgment undertaking load calculations. The problem is that there are numerous variations on assumptions used when doing load calculations including the climate and future additions, as well as the designer’s experience.

Building inspectors don’t normally review load calculations for accuracy, which makes this a primary responsibility of the designer.

A similar scenario applies to equipment and system sizing, which, like load calculations is a vital element of good mechanical design. In addition to the availability and cost of equipment, there are a number of parameters that designers must consider, including sensible and latent loads, duct design, airflow, operating warm-up and cool-down sequences, and the location where equipment will be installed. While Standard 90.1 does take various parameters into account, in reality, there are so many possibilities, their requirements don’t have any practical effect on energy consumption.

Sizing requirements, like load calculations, aren’t explicitly enforced by building departments and local authorities. However, engineers have a legal responsibility to size and specify system equipment properly. Ultimately, the requirement is for systems and equipment to be specified correctly on the plans, and then, if necessary, a field inspector can do on-site inspections to ensure the system has been built in accordance with the approved plans.

Ventilation & Fan Power

If people are expected to remain in enclosed spaces for extended periods of time it is essential that these spaces are continuously vented with outdoor air. COMcheck refers to local codes for minimum ventilation requirements or to the International Mechanical Code (IMC).

When it comes to fan systems, COMcheck requires that they are operated continuously (when the space or room is occupied) to meet the provisions of the IMC. Additionally, a thermostat capable of being set to run continuously must be used, and systems must be capable of reducing the outdoor airflow to minimum levels using control dampers or fan volume controls either manually or automatically.

Another important element that COMcheck covers is the use of natural ventilation through windows, doors, louvers, and so on to ensure compliance. But users of the software are referred to local codes and the IMC for acceptable minimum opening areas that will ensure there are adequate natural ventilation rates.

The IMC allows natural ventilation to be used instead of continuous mechanical ventilation and it contains provisions that must be met if ventilation is provided via non-mechanical means. The IMC takes human response into account and allows occupants to ventilate spaces by opening windows and so on if they want to allow outdoor air into rooms. Acknowledging that they have the ability to control this type of ventilation, the IMC doesn’t expect it to be a permanent form of ventilation (in other words it doesn’t have to remain open all the time.)

While COMcheck does place limits on air handler design in variable flow systems, there are no limits on fan power in terms of W/cfm, which is how the efficacy of fans is measured. But this is simply because it was felt that the Standard 90.1 required couldn’t be enforced. Nevertheless, system designs that use the type of HVAC equipment allowed by COMcheck typically use less fan energy than the maximum allowed by Standard 90.1.

In terms of fan control technologies, COMcheck requires more efficient fan airflows that start at 25 hp rather than 75 hp required by the 90.1 code.

Service Water Heating Systems & Equipment

Energy codes provide minimum criteria to effectively heat and deliver hot water, as well as insulate circulating hot water systems, service water heating equipment performance efficiencies in commercial applications, heat traps, controls, and pool heaters.

However, COMcheck only covers water-heating equipment that is included in Federal efficiency regulations, primarily the Energy Policy Act, Public Law 102-486. Also, the water-heating equipment efficiency levels that are equivalent to those in Standard 90.1 are mandated as an EP Act manufacturing standard. This means that all types of water-heating covered will comply with efficiency levels in the 90.1 code.

Water-heating equipment that is covered includes:

- All types of electric water heaters

- Fuel-fired:

- Storage water heaters

- Packaged boilers that are used as water heaters

- Instantaneous heaters, which, in terms of the EP Act means a water heater that has an input rating of at least 4,000 Btu/h per gallon of water stored

- Pool and spa heaters

Other equipment and issues that are addressed through the EP Act Public Law legislation include:

- The efficiency of service water heating and minimum manufacturing standards for equipment efficiencies

- Electric and oil service water heating standby losses

- Unfired storage tanks

- Storage volume

Gas and oil waters heaters with a storage volume greater than 140 gallons are not covered by Federal efficiency regulations and their use is only permitted under the Complex Systems section, not the Simple Systems section.

In terms of piping insulation, both Standard 90.1 and COMcheck have requirements for vent or flue dampers on water heaters, though this is waived if there is no electrical supply, as well as for heat traps on non-circulating water-heating systems.

Requirements for hot-water temperature settings were incorporated in Mechanical COMcheck, but because they were extremely difficult to enforce, they were removed. However, the Standard 90.1 requirement for automatic time-switch controls on circulating hot-water systems has been maintained in COMcheck. There is also a COMcheck requirement for time-switch controls if heat tracer tape is used with circulating systems. This is intended to prevent the use of circulating water to prevent freezing when heat tracing is provided for.

COMcheck maintains the requirement for swimming pools to have shutoff controls that are readily accessible, as well as time-clock switches for their heaters and pumps. There are though exceptions to the time-clock rule for site-recovered or solar heating, in keeping with Standard 90.1. The Standard 90.1 exception for pools with more than 70% of the annual energy for heat supplied from site-solar or site-recovered systems, which requires a compliance officer to certify the annual fraction of heating energy from different sources, is no longer included in COMcheck. The result is that the COMcheck requirement is both more restrictive and more easily enforceable.

Perhaps surprisingly, water conservation requirements are not included in COMcheck. However, the EP Act Public Law legislation addresses appliances that use water, so it is assumed that all new toilets and showerheads will meet this manufacturing standard.

COMcheck and Codes

As discussed earlier, COMcheck supports various codes and standards, including the IECC, so from time-to-time changes are made to the software to ensure it complies with the international energy and other codes that are constantly updated.

This is why NY Engineers uses the most up-to-date version of COMcheck, which is updated every three years, most recently in November 2018.

There is absolutely no doubt that it is one of the best ways to ensure that mechanical engineering designs are compliant.