Our dry sprinkler systems are reliable. We know how damaging fire can be and so we design and install the best sprinkler systems.

Dry sprinkler systems can be expensive with lots of component parts and air pressure supply. Nonetheless, we always strive to keep costs low without compromising the quality.

All of our systems are designed with longevity in mind, saving you maintenance costs down the line.

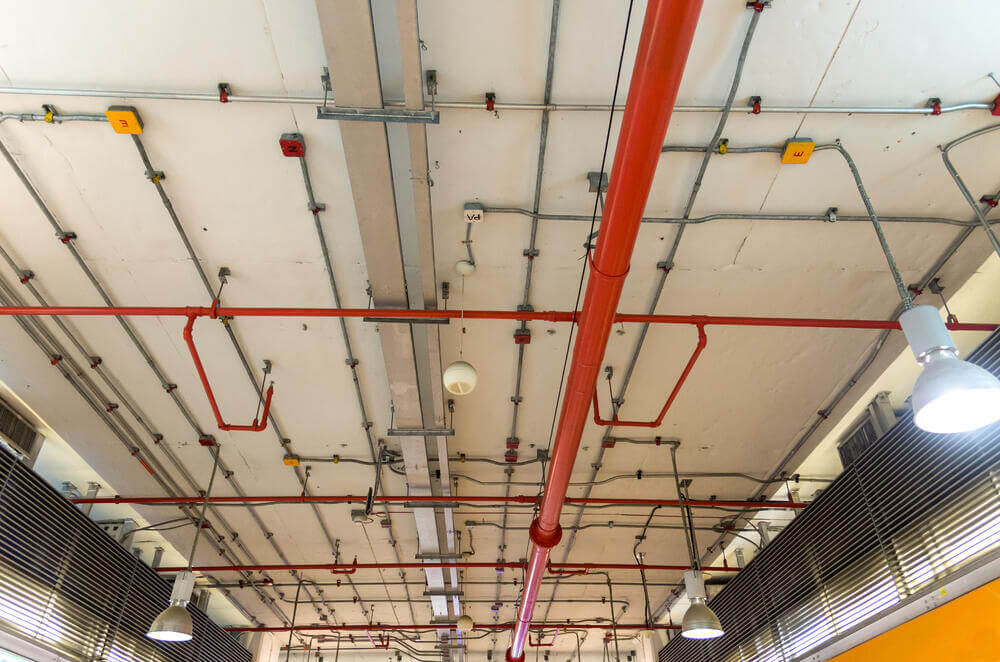

The dry sprinkler system can be quite complex with lots of valves to keep checking at the sprinkler riser site. The idea behind the pipes being dry is to prevent freezing of water when this system is installed in unfavorable temperature conditions that regularly falls the freezing point. We will help you assess the situation to check if you need the dry pipe or wet pipe sprinkler system. Nearby Engineers New York Engineers always ensures that the sprinkler riser is functioning optimally with all the valves, alarms and the drains checked. The efficiency of this system lies in its design, installation, and maintenance.

We are one of the fastest growing MEP design firms in the construction industry. We pride ourselves on having a fast turnaround while providing cost effective solutions. We are licensed in 50 states and are your one stop shop for all MEP design needs.

We are licensed in all 50 states!

We design to the perfection

Enjoy our lightening fast turnaround

We have completed so far!

Our designs are approved by DOB in one go

The best service experience in the market

The definition of this system lies in its naming: “dry”. What this tells you is that, unlike the wet pipe sprinkler system, water is kept clear from the sprinkler heads until such event that the sprinkler heads are activated by a fire break out.

We design quality sprinkler heads and fire detectors as well to give you a full combo of a dry pipe sprinkler system. These heads work normally like in the wet sprinkler system where they are held in place by a liquid-filled class that gets broken when temperatures are high. Once it breaks, the air pressure in the piping network decreases thus prompting an imbalance of pressure between the air and water. As a result, water will flow into the system to exit through the open sprinkler heads.

The dry sprinkler system can be quite complex with lots of valves to keep checking at the sprinkler riser site. The idea behind the pipes being dry is to prevent freezing of water when this system is installed in unfavorable temperature conditions that regularly falls the freezing point. We will help you assess the situation to check if you need the dry pipe or wet pipe sprinkler system. By comparison, the dry pipe system can be expensive to install the wet pipe.

With this dry pipe sprinkler, there’s typically a dry valve that keeps the water from the pressurized air or nitrogen in the piping. As per the specifications, we design the sprinkler riser in such a way that there are two pressure gauges: one for the pressurized air and the other for water.

The pressure differences or ratio has to be kept in check. Usually, it is at a ratio of 3:1. For example, water pressure may have a pressure of about 120 psi while the pressurized air has 40 psi. Don’t worry if all these seem too technical. Our engineer on the site will explain all these in a layman’s term.

The above concept should be clear enough on how this system works. To start with, this system is similar to the wet sprinkler system apart from the segregation of water and pressurized air.

In an apartment, you would normally sprinkler heads aligned per specifications to offer full coverage. Once fire emerges, the liquid that keeps the sprinkler heads closed will expand and then break the glass. Consequently, the head will open thus letting the pressurized air or nitrogen exit. This, in turn, decreases the pressure in the pipe.

What happens next? The dry pipe valve is burst open by the differential pressure because air has been discharged. Water will flow at high pressure to the open sprinkler heads and then get discharged to the adjacent fire break out.

Like in the wet sprinkler system, only the sprinkler head in proximity to the fire gets actuated while others remain closed. If the fire is hot enough in a small room, other sprinkler heads may be burst open too due to the expanding liquid.

Note that the water will get discharged continually unless deactivated manually at the valve if the fire has been extinguished. The purpose of the sprinkler is to suppress the fire until relevant firefighters arrive at the scene. In a process of discharging water, the alarm at the sprinkler riser will be triggered to alert firefighters and occupants of the building about fire.

Nearby Engineers New York Engineers always ensures that the sprinkler riser is functioning optimally with all the valves, alarms and the drains checked. The efficiency of this system lies in its design, installation, and maintenance.

Like we highlighted above, one needs to deactivate at the sprinkler riser to stop the municipal water flow after the fire has been extinguished. However, the system needs to be replenished. The pressurized air does not fill automatically. Our engineers will ensure that the system goes back to normal by refilling the air or nitrogen.

We will reconfigure the pressure settings to create a balance between water and the air in the pipe. But, prior to refilling the system, we have to ensure that the pipe is dry to avoid any possible corrosion due to some water left in the pipe. This is where the wet pipe sprinkler gets the thumbs up because water is constantly in the pipes and so corrosion is less likely to happen. But that’s not a big deal when you have Nearby Engineers New York Engineers in your midst.

As we said, the dry sprinkler system can be complex to design, install, configure, and maintain. There is too much of labor involved here hence the associated expensive costs. Nonetheless, we will strive to keep your costs low with no quality compromised.

Well, sprinkler systems, in general, are required by NFPA standards to be installed in premises for fire protection purposes. This is a general requirement and does not specify which sprinkler in particular, but often implied it refers to the wet pipe system.

A wet sprinkler system is more popular than any other sprinkler. Note that you have four basic sprinkler systems: deluge, pre-action, wet pipe, and dry pipe system. Do they really differ to that extent? We design, install and maintain all these sprinkler systems so know everything and differences about that.

Deluge:it has open sprinkler heads and the same piping network as others with a major difference at the sprinkler riser. When triggered, all sprinkler heads will discharge water simultaneously. This system is best suited for areas likely to have blazing fires. It is relatively powerful than others.

Pre-action:it is not that too different from the deluge in that the sprinkler heads are closed until triggered by the fire. As in the name, pre-action, action is required to actuate the sprinkler heads.

Wet sprinkler system:We have highlighted this many times already and you should have a glimpse of how it works by now. Basically, the water is always pressurized in the pipes and it is ready for action. When you hear building installing the sprinkler system, it is often the wet pipe system for its many advantages except its inefficiency in temperatures below the freezing point of water.

The last one would be the dry pipe system which this article is about.

The dry pipe system is needed in temperatures that are not favorable to a wet pipe sprinkler system. Pipes would freeze and the water would also freeze, expand and then break the pipes, which then leaves a messy ordeal if the wet sprinkler system is installed in extreme temperatures. NFPA 13 also governs the installation of the dry sprinkler system and also stipulates the specifications.

Some customers often ask us this question that which one is really the best. Well, there is not really the best among the two except their operating conditions. But, all in all, wet sprinkler system takes the trophy with its convenience apart from its proneness to freeze in inclement temperatures.

Once the fire breaks out, the wet sprinkler system is already ready to dispense water in a higher amount to suppress the fire. This happens instantly once the sprinkler head is burst open. That said, the system has the ability to act on the fire in the moment’s notice. The fire will have fewer chances to advance.

Dry pipe system, on the other hand, has a lag. It would typically take up to 60 seconds before water is discharged. This is attributed to the time it takes for the pressurized air to be expelled from the pipe before the water reaches the sprinkler heads. Anything can happen in 60 seconds. For instance, the fire could have extensive damage before reaches out. Thus this shortfall makes wet pipe sprinkler systems the best when coming to response time.

The cost factors of these systems include their components, installation, design, and maintenance. By looking at their designs, the dry sprinkler system has more components than the wet sprinkler system due to its complexity. You have extra valves which are factored in the pricing. For this reason, dry pipe system is more expensive than the wet sprinkler system.

It needs more labor to install a dry pipe system. Our engineers will, however, factor that out when installing your system. This makes us the best as we strive to provide quality services at affordable prices. Also, factor in the pressurized air or nitrogen in the pipes. All these incur costs on the system which then makes the wet sprinkler system preferable in favorable conditions.

Even maintenance wise, it is easy to maintain a wet pipe system with fewer components. You would stop water supply and attend the problematic components. With the dry pipe system, you may have to discharge the pressurized air to fix its piping. You still have the water piping too to fix. All is done at the sprinkler riser.

We excel in the maintenance of all these systems as the pioneer of sprinkler engineering and fire protection services. Leave all these maintenance concerns to us. NFPA 13 and 72 requires a good-working conditions of these systems. The systems have to be maintained for specific range of periods. We are well-rounded with these specifications and will therefore keep them in mind at all the times to ensure compliance.

Not all environments are favorable to wet pipe systems. In temperatures that fall below the freezing point of water, dry pipe systems are best options. To be precise, dry pipe sprinkler systems are needed in areas where temperatures cannot always be kept at a minimum of 40 degrees Fahrenheit as per NFPA 13 standard. Because the pipes are not filled with water, it is less likely for them to freeze.

Usually, applications of this system include the following:

There are many applications which our engineers can advise you about upon meeting. The only nuisance with wet pipe system is that you always have to keep the temperature in check. Otherwise, it would be a perfect system to use in all cases.

Every sprinkler system has its cons and pros. Weigh your options by reading the downsides of this system below:

There are a plethora of water sprinkler systems you can use to protect your property and human lives against possible fire emergencies. The dry sprinkler system is the second most popular following the wet sprinkler system. Nearby Engineers New York Engineers designs, installs and maintains the dry pipe sprinkler system to NFPA 13 standards.

We have remarkable success in the industry already with our sprinkler engineering services. Whichever sprinkler system you need, we can sort you out. We design, install and maintain sprinkler systems in line with the enforceable standards in Chicago.

Dry sprinkler systems may be complex and expensive to install but with Nearby Engineers New York Engineers the process becomes relatively simple. Our engineers are revered in the industry due to their unmatched specialized skills in installing and designing these systems.

We have a faster turnaround than all our competitors. If you need advice regarding the choice of the sprinkler system, we can offer that too before the design.

382 NE 191st St , Suite 49674

Miami, Florida 33179276 5th Avenue, Suite 704 #904

New York, NY 10001