Comparing Steel Construction and Concrete Construction

Concrete and steel are among the most common construction materials, and many building projects can use either of them for their underlying structure. Each material has advantages and limitations, like in any engineering decision, and this article provides a general comparison. No material can be considered better than the other for all cases, and the best option is determined by project conditions.

Reduce the cost of your next construction project.

Concrete Construction

Concrete is the second most used material in construction after water: it offers versatility, durability and easy fabrication, and can be molded in any shape.

-

Concrete structures are very resistant against compression, but cannot handle tension effectively.

-

For this reason, most concrete structures are reinforced with steel bars that provide additional support for tensile loads, and this combination is called reinforced concrete.

Concrete structures can be built in several ways, using different types of concrete. The three most common types are plain cement concrete, reinforced concrete and prestress concrete.

Plain cement concrete is obtained by combining cement, coarse aggregate (gravel), fine aggregate (sand), and water in predetermined proportion according to design needs. When hardened, these materials become a homogeneous mass.

-

Structures made with plain cement concrete have a high compressive strength but almost no tensile strength.

-

Therefore, plain cement concrete is mostly used in roads and concrete blocks for walls, since these structures are subject to compressive loads.

Reinforced concrete is basically plain cement concrete with steel bars that provide additional tensile strength. This is the most common type of concrete used in construction, having applications not only in buildings but also structures such as water tanks.

Prestressed concrete is preloaded by applying compressive stress before it is subject to any load besides its self weight. The compression is produced by tensioning high-strength steel tendons within the concrete volume before the application of external loads. This improves its performance once in service.

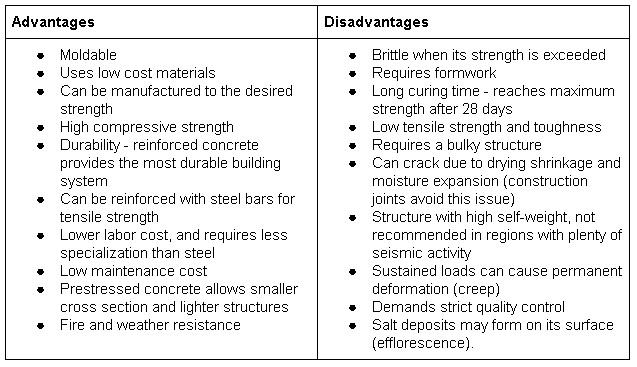

The following table summarizes the advantages and disadvantages of concrete structures:

Steel Construction

Steel is an alloy of iron, carbon and other elements. Depending on its chemical composition, it is classified as mild steel, medium carbon steel, high carbon steel, low alloy steel or high alloy steel.

As implied by its name, structural steel is a category of steel used in the construction industry. Structural steel shapes and properties are regulated by standards such as those from the American Institute of Steel Construction (AISC).

-

Most structural steel shapes are elongated beams, with a specific cross section.

-

The most common shape is the I-beam, which is very stiff with respect to the cross-sectional area. Therefore, it can support high loads without deformations

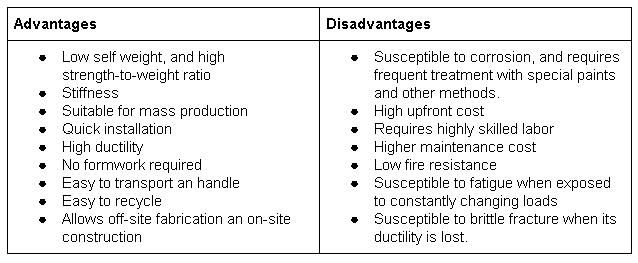

The following tables summarizes the advantages and disadvantages of steel construction:

Direct Comparison Between Concrete and Steel

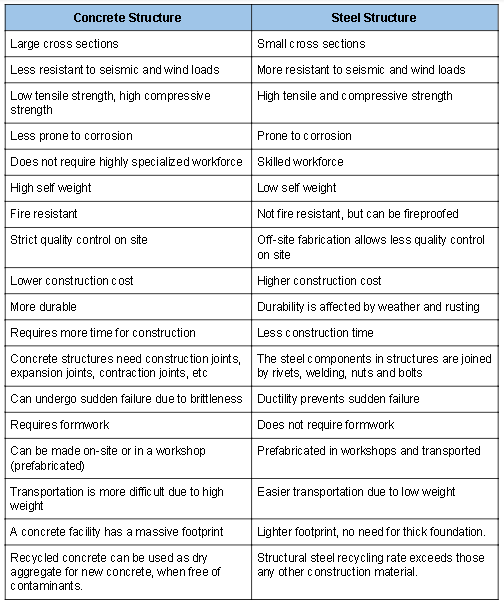

Both materials provide numerous benefits, as described in the previous sections. When choosing between a concrete structure and a steel structure, the following differences can be expected:

The most suitable construction material for your building is determined by specific project needs. For example, concrete allows lower construction costs in exchange for a longer construction time, while steel is preferred when fast construction is the priority. In cases where space is a limitation, steel saves space compared with the bulkier concrete structure.

Nearby EngineersNew York Engineers has a MEP design track record of 1,000+ projects. Contact us via email (info@ny-engineers.com) or phone (786) 788-0295212-575-5300, and make sure your building systems meet codes.

Keith Fink

Keith is the Franchise Brand Manager at NY Engineers, Keith is all things related to our project portfolio, brands and all things you need to know before we start your project.

Join 15,000+ Fellow Architects and Contractors

Get expert engineering tips straight to your inbox. Subscribe to the NY Engineers Blog below.