Our MEP Engineers design to keep things at the high 90s in terms of relative efficiency without compromising on the functionality of the panel.

Safety is a product of the precision application of knowledge, keeping good safety factors and doing quality work, what’s a better choice for that than our professionals?

NY Engineers apply their knowledge and experience to provide you with the most specifically customized plan for your system, after all, this is what panel scheduling is all about.

Panel scheduling plays a critical role in affirming the power consumption of the installation and operations of all sorts of design projects.

Our MEP Engineers use the information obtained from this to validate the overload stage, implementing safety precautions accordingly, and therefore design the overall system, namely, the system of control, conductors and conduits. It is designed using different calculations, the load scheduling is done during the design stage of installation. It is also to be noted that additional loads are projected; to give some leverage to the designed system in the case where more load is obtained in the future, by the panel board.

We are one of the fastest growing MEP design firms in the construction industry. We pride ourselves on having a fast turnaround while providing cost effective solutions. We are licensed in 50 states and are your one stop shop for all MEP design needs.

We are licensed in all 50 states!

We design to the perfection

Enjoy our lightening fast turnaround

We have completed so far!

Our designs are approved by DOB in one go

The best service experience in the market

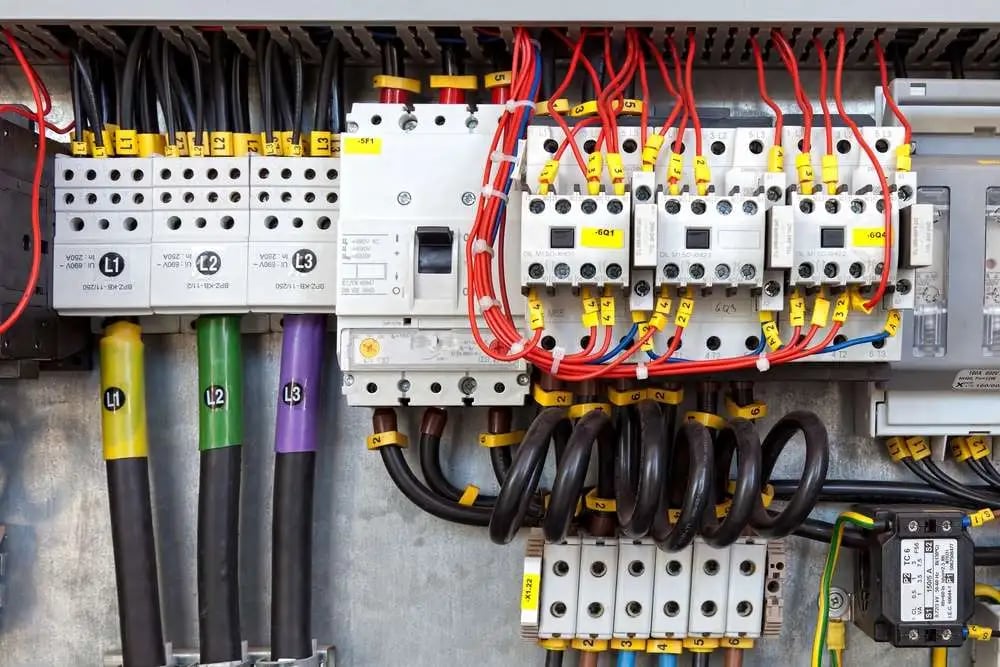

Panelboards, which are also known as electrical distribution boards, are a part of the electrical supply circuit, in fact, a core part. Its function is to distribute the electrical power in terms of secondary circuits, protective fuses and breakers per unit circuit.

All this is neatly packed within an enclosure which we call the “Panelboard”. It also consists of the main switch to control the overall power supply and residual current breakers with protection against the excess current. If you ever see, breaker panels, fuse boxes, fuse boards, consumer unit (CU), or circuit breakers, then this board is what they’re talking about.

From stability on peak hours, to cost reduction, there are many advantages of Panel Board Scheduling. Some of these advantages are discussed below:

During the design stage, Panel Board Scheduling automatically helps choose the right system for control, conductors and conduits. It also helps cater to the extent of future loads that may be operated, thus providing a good safety factor and future proofing.

Our technicians cater to the time factor too in terms of peak hours, normal hours and low consumption hours. It estimates the right amount of electrical load with respect to each category. So in essence, the design can then cater to the extra loads provided in the future and it may also project and advice for expanding, to the owner.

Lastly, it is really good at power management. If the load is having a tendency to fluctuate between a high peak and the lowest consumption because of the type of use, the panel scheduling would be able to pull a scheme within which the load is kept at par and stable. This overall can also help bring down the overall cost of electricity consumption during the peak hours and thus allow the consumption of lesser energy for the same applications, increasing the efficiency greatly.

NYE Design Engineers perform the load calculations and making sure that no panel ever reaches the stage of overload.

As they share some of their experience with you, here is some of the information required from a broader perspective that helps harness the effectiveness of this design tool:

The first step is to figure out the total list of loads within the “system” we have chosen. The “system” would be the facility or installation. Then the loads are to be specified as either process or non-process. Process loads and the non-process loads are the electrical loads supplied to the installation using the power system and are influenced by the load schedule. Moving on, the absorbed power, power factor, and efficiency is the parameters are required to design the panel board schedule.

Process Loads

ASHRAE suggests these loads are related to the manufacturing process, industrial process or some kind of commercial process, which is basically not related to providing the occupants with comfort. It can be the compressors, motors and so on.

Non-Process Loads

These are the supplementary loads which help provide the occupants of a building with comfort and amenity. It can include the HVAC systems, the lighting, utility system and so on.

Absorbed Power

Generally, the information on absorbed load is not readily available. It is the approximate power that the load will “actually” draw; it’s always lower than the rated maximum capacity. Due to the fact that it’s not always clear, we take it as around 80 to 90 percent of the rated capacity.

Power Factor

This corresponds to the portions of the panelboard schedule that are reactive. If the power factor is not available there’s a convention to be used for each type of load, like for heater it’s 100%, for the motor, it’s 85% and so on.

Efficiency

Usually, the efficiencies of these loads lie in the range of 80% to 95%, and this efficiency corresponds to the difference in the amount of electrical energy obtained and how much of it is converted into the mechanical energy.

Voltage : For any given load, identifying the voltage level is the key thing to do, because it tells us about the location (a primary factor) of it on the switchboard. There are three main locations, HV, MV and LV, which mean Heavy Voltage, Medium Voltage and Light Voltage respectively. The Heavy Voltages correspond to a range of fewer than 150 kilowatts. The Medium Voltages correspond to 150 kilowatts to 10 megawatts. Finally, the Light Voltages correspond to more than 10 megawatts of power.

Load Duty : Duty is the relation of loads to the factor of time. For the purpose of Panel Scheduling, the time frame considered is 24 hours. Within this, load duty is used to categorize standby, irregular and uninterrupted loads.

Load Criticality : Each load is considered either normal, essential or critical, based on that their importance to the main process is quantified and thus the design is implemented accordingly.

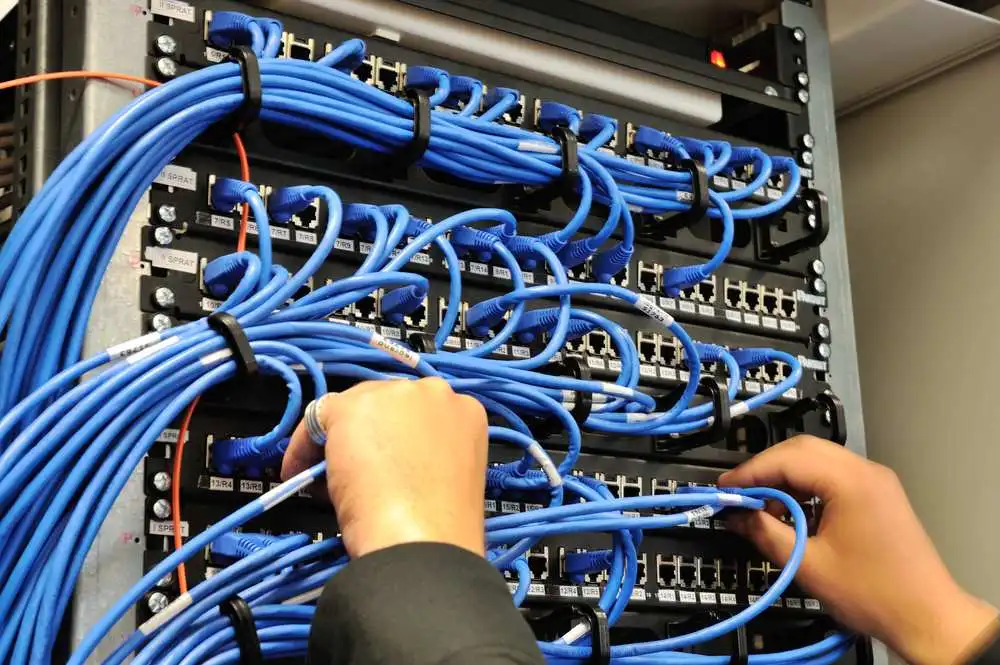

The first step is to introduce the feeder pipe and install the board with a connector. Then the connector threads should be covered with plastic lining, that is, if you’re utilizing a metal pipe in your design. The screws should be inserted in the openings towards the back of the panel with the panel being leveled.

Then our technicians pass the electrical feeder wires through the feeder pipe and make sure to leave enough wire, so it can reach the backside of the board. There would be two black wires, shape them by bending them and then establish a connection to the main breaker.

After that, they will connect the neutral wire to a silver-hued bar having little screws for connection, this is the neutral bus. Making sure to also connect green and exposed copper wires with ground neutral bar.

Finally, they make sure to keep an eye on the rating of the breaker and thus connect the wire with a suitable diameter to take on the load.

Panel Scheduling Process is widely accomplished with the help of software; there is much tailor-made software out there to fulfill specific needs. Our Engineers are well versed with both custom software based on your needs and the general use of Excel to fulfill the purpose.

Our toolkit is vast. Some of the capabilities that our engineers have due to their software are Dynamic updates for Panel Schedule, panel load calculations for both continuous and non-continuous loads, detailed summary for the loadings in panel schedule and intelligent panel design with proper calculations. There is also load modeling through an internal spreadsheet, a comprehensive library for feeder and cables, unlimited branch circuits for panel boards, and sub-panel connections too. NEC, ANSI and IEC, code Factors referring to Panel Loads, Libraries referring to the control device and ultimate protection, code factors pertaining to the panel loads, and so much more.

Our engineers are also well-versed in the use of Revit Software. Revit software can help produce flexibility in process scheduling. It does it through its vast features like making the loads relatively equal to each other, by a single click, with the help of rebalancing tool, in essence, this can redistribute loads before you even blink.

Great customization options allow engineers to shift the circuits around without affecting the other circuits in the panel. The unused slots can be labeled as spare spaces which can also be locked to a slot.

It helps our professionals create unique templates to match your company’s requirements and standards complying completely with your needs. There are least errors in this way of panel scheduling and it’s easy and efficient. Time is money and we save it for you without a compromise on results!

Due to a vast amount of experience and running into many life lessons due to occasional failure that comes with time, our MEP engineers have had the software tweaked to suit all kinds of scenarios, even the ones which go unnoticed by the most experienced of engineers out there.

Some of the factors that give us the edge are:

NY Engineers have a mission to deliver the best, world-class electrical panel schedule designing and drawing services and solutions based on the systematic and creative approaches of the international standards.

Our team is experienced and their strengths include, quick solutions, consistency, and resourcefulness, cost-effectiveness as a priority, good teamwork, great client-engineer relationship, fast response, and an overall ingenuity to be the best.

We believe in the safety of our client and their resources more than anything, although, on the same note, we also understand your need to get on with things as quickly as possible and our professionals would be on the same page.

It is safe to say that hiring NYE would be the way to go for Panel Scheduling due to its technicalities and background knowledge. Our engineers deliver the best design ensuring absolute safety, cost-effectiveness, the efficiency of the system and durability of work. So for the years to come, your panel system stays sustained and thriving!

382 NE 191st St , Suite 49674

Miami, Florida 33179276 5th Avenue, Suite 704 #904

New York, NY 10001