Steel Structure Design

Reduce the carbon footprint and get LEED-certified when you utilize steel for its 100% recyclability.

Reinforce concrete with steel for dual compressive-tensile protection against earthquake, wind or snow loads.

Integrate BIM and VDC from the early design stage to the facility management of your steel building project.

Steel is at the top of the list in the sustainable materials, what with its 100% recyclability from start to the end of its life cycle assessment (LCA). Know that when you choose steel as your main building material, you'll recoup maximum paybacks on your investments through sustainable advantages from cradle to grave.

In a layperson's perspective, the higher purchasing price of steel compared to its counterparts might undermine its superior performance as they regress back to low-cost, but fair-value materials for cost-saving measures. But for our expert set of eyes, we beg to differ. In fact, New York Engineers believe that the far-reaching benefits of steel will outweigh your expensive upfront costs, since these returns can come in the form of economic, social and environmental advantages down the line—summing it all up for the three pillars of sustainability.

Our environment-conscious civil engineers advocate the use of steel structure design for your building project, where we amplify our sustainable efforts by utilizing energy modelling for each applicable stage, starting from:

Opening the cyclical loop of steel production starts with raw materials, where we utilize 3D modelling for energy analysis on the streamlined steel design to fabrication workflow. Steel by-products that do not make it past this stage can be transformed to ground granulated blast furnace slag (GGBFS), where you can utilize this as a sustainable replacement for cement in a concrete mixture.

Fast forward to site logistics, where your steel structure design can either go two-way: reinforced concrete or prefabrication. The impact of carbon footprint is dependent on these two options, since the latter offer more cost-effective options in its off-site fabrication and quick in-situ installation, while the former can be labor-intensive due to rebar placement on concrete—owing to higher construction costs. Steel crap will accumulate over time as it undergoes the 50-year use phase, and any remaining waste from the demolition can be reused and recycled back into the loop—closing the previous loop and starting another yet again in its unending sustainable cycle.

When you know the intrinsic characteristics of steel, you can weave through the intricate ins-and-outs on its cradle-to-grave lifecycle—and New York Engineers is excellent at finding opportunities where others see problems. All these and more are factored into the steel structure design, where you can best use our sustainable expertise for your advantage.

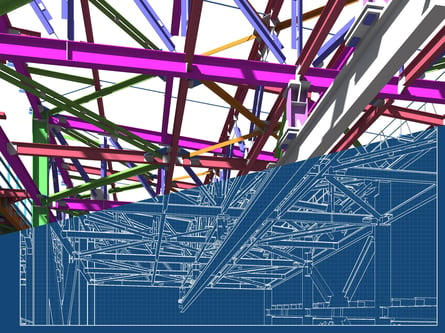

If you think that your 2D drawings are the most comprehensive set of details you have ever seen, wait until you see the wealth of knowledge that you can get with BIM. This data-rich process causes all sorts of paradigm shift in the AEC industry, where each industry specialist have their own BIM tool curated to their own expertise.

Together with New York Engineers, let's take a look on how the flow of steel structure design efficiently move from design to construction and operation through a BIM-integrated platform:

We take matters into our own hands by overlaying the architectural master model with steel structural model. Through BIM-based Revit, our civil engineers optimize the structural integrity of your building by performing structural analysis on your steel components and connections. What we can do as your trusted experts is to design and specify the minimum load requirement for your steel columns and beams based as per the stringent 2018 International Building Code to get your steel structure design up-to-code.

Entering this phase means you have your construction documents ready in a digital collaborative platform, where detailed design can range from cutting lists to bar bending schedule, and just about any other steel details needed to mobilize your steel structure design. Best to know that you have BIM as your design point of reference anytime there are clash trade interferences in-situ, such as building services taking up the geometric space for your steel components.

Backed with data from design and construction, you can utilize this information reference for future renovation, addition, alterations or structural retrofitting. As such, you can better prepare your steel structure design for disaster resiliency in any such cases that earthquake, hurricane, seismic or wind loads hit your building facility more than the specified structural load. Proactive planning of operations and maintenance (O&M) is possible with BIM.

Think that virtual constructability review is just a blip on the radar due to its short time allocation between post-design to pre-construction phase? Think again. Conducting one might just make the success of your steel structure design. All the more that you need to invest in an efficient civil engineering foundation such as in our case to compensate this shorter review time with superior level of professional expertise.

When you check for the constructability of your steel structure design, components can range in all kinds from structural steel to reinforcing bars and mild steel.

Hover below for some civil engineering tips on what to look out for when assessing the buildability profile of your steel components:

Here's where you can make a critical turning point in your steel structure design: integrate 4D BIM and 5D BIM right at the very start with fabrication. As experienced engineers, we know the inclination of steel components on the long-lead spectrum, hence we act with proactivity in cutting the great divide between the long waiting time from design to fabrication through efficient generation of shop drawings and bill of materials—all thanks to the data extraction and automation features of BIM.

To be more specific, we split the macro process into shorter intervals for batch procurement orders on priority steel items.

Below, our skilled civil engineers show you how BIM revolutionizes the fabrication industry in light of steel structure design production:

For better optimization on your cost, schedule and quality constraints, much better to stick with a parallel design-bid-build workflow than a linear one. This way, priority areas in need of prefabricated items for critical path management can mobilize for start date on-site, all while non-priority steel items located above grade or in superstructure can revel in longer lead times.

Whether your steel structure design leans onto the macro steel framing or composite type such as reinforced concrete, one thing's for sure: New York Engineers orchestrate the site logistics scene in much the same way as a conductor-choir analogy.

Through digital facilitation, we disrupt the industry by challenging conventional logistics with live features in the on-site BIM modelling, such as:

Enter plasticity and high strength-to-weight ratio—it's no wonder why steel ranks up and gains popularity in the realm of construction materials. But most importantly in all its intrinsic characteristics, steel is famously renowned for its high tensile strength. It is for this very reason that we partner up steel with concrete for a tensile-compressive duo respectively—neutralizing the opposite load forces for optimum engineering design.

Since foundation design is the first in line with critical path management, this particular structural package gets a jumpstart from the dual benefits reinforced concrete provides. What we do at New York Engineers is to conduct geotechnical investigations for soil sampling, and calibrate the reinforced concrete foundation design as per soil bearing capacity, load factors, and superstructure specifications. Extensive as it may, but our seasoned engineering veterans are experts in handling even the most complex cases of structural design.

Through virtual design and construction, it's easy to visualize your steel structure design from early planning to as-built phase. Move away from old-school paper and pen sketching and 2D blueprints where you have a limited axis. Open up for more opportunities on innovation through sensor-equipped construction sites and unmanned aerial vehicles (UAV) powered by Internet of Things (IoT). As such, point-cloud modeling from laser scanning and reality capture excels on efficiency by replacing intensive manual labor tasks with intelligent algorithms for survey inputs.

Stepping inside into the virtual world can offer you immersive visualization experience, while virtual trade coordination among project stakeholders may be in place to reduce field rework and change orders—garnering you a holistic success on the aesthetic, functional and structural scale of your steel structure design.

Stand tall with your steel structure design. Steel has long been in the game for centuries, owing much of our historical landmarks to its superior material characteristics. Up until today, steel structure design remains as dependable as it is—shaping your future with sustainable advantages from start to the end of its lifecycle, and all while remaining as strong and functional in style for its modern applications.

As we delve into the post-modern era where Information Age will only get as good as it gets, New York Engineers remain as the industry leader in integrating civil engineering expertise with technological intervention. We pioneer and advocate the paradigm-shifting workflows, curating each to our own expertise in collaboration with all project stakeholders for effective elimination of communication barriers. Steel market is ripe for innovation, and with the cutting-edge technologies at play, the supply chain management will affect each AEC industry specialist on the design, fabrication, construction and operation of steel structure designs.

Scan our established steel-specific project portfolio, where we merge the traditional working principles with the advanced digital technology for your all-in-one advantage. Learn more of how New York Engineers can help you forge greater heights to success with your steel structure design