Our HVAC solutions are designed to ensure optimal comfort, regardless of outdoor temperatures.

We identify & eliminate unnecessary energy consumption, leaving you with maximal functionality for the minimum annual energy cost.

All of our systems are designed with longevity in mind, saving you maintenance costs down the line.

Click to view PDF in detail

Click to view PDF in detail

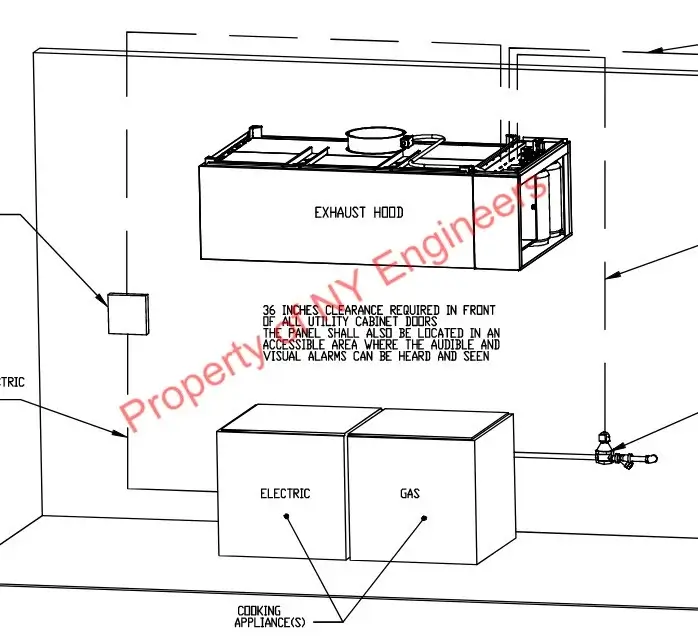

Commercial Kitchen Hood Ventilation is one of the most important design elements in the commercial cooking setting. The functioning of a properly installed exhaust and ventilation system not only maintains the air quality it also aids in maintaining the temperature of the kitchen as to reduce the strain on the other appliances at use.

Commercial kitchen hood ventilation is best done in collaboration with a trained professional like a mechanical electrical plumbing engineer otherwise known as an MEP engineer. An MEP engineer will be able to guide and direct you, your construction team, or your general contractor in what the overall consideration for your commercial kitchen hood should look like. Working with an MEP engineer will also assure that it will ultimately be installed and operate safely, within code and function to keep the kitchen operational.

We are one of the fastest growing MEP design firms in the construction industry. We pride ourselves on having a fast turnaround while providing cost effective solutions. We are licensed in 50 states and are your one stop shop for all MEP design needs.

We are licensed in all 50 states!

We design to the perfection

Enjoy our lightening fast turnaround

We have completed so far!

Our designs are approved by DOB in one go

The best service experience in the market

The commercial kitchen hood ventilation is specifically designed to help contain the many air contaminants and temperatures that are created in a commercial kitchen. These elements include heat, smoke, grease particles, and vapor. The core purpose of the commercial kitchen hood ventilation is to avoid health and fire hazards. It is important to note that each kitchen is unique unto itself and there is no ideal solution for every commercial kitchen design. Different foods will require various equipment to prepare it and therefore the ventilation needs to be tailored to the individual needs of the kitchen.

Commercial kitchen hood ventilation is all about finding the proper balance in the air quality this means that for the contaminated air that is removed from the facility the proper balance of air needs to be returned into the building. This places the commercial kitchen hood ventilation at the central focus of industrial kitchen design-build process. Without the proper ventilation system, the kitchen would be an unbearable environment to work. Without the proper design specifications included in your kitchen, you could create a negative pressure situation in your building that will result in the building pulling air from other areas like pipes and drainage resulting in very unpleasant conditions for the buildings visitors.

It’s important to consider that while shopping for a new ventilation system, the full setup must be properly fitted and measured for your specific commercial kitchen needs. A commercial kitchen hood ventilation is one of the most important and expensive investments when building a commercial kitchen. Without ensuring that the setup is functioning properly, you will continue to have air balancing issues which will not serve your kitchen or the building.

A commercial kitchen hood ventilation is made up of three main components including

Each of these components will work together to develop a system to clear the air of contaminants like grease, grease vapor while also eradicating the air of odor, organic compounds and removing moisture. The start of this process lies with the exhaust fan as it creates a reverse draw of air that will remove smoke, steam, heat and grease vapors from your kitchen. We can’t stress enough the importance of a custom Commercial Kitchen Hood Ventilation to the overall functioning of a successful commercial kitchen.

As you are firming up your design it is important to work with a team of certified professionals to assure that safety and codes are met before you start your cooking operation. A mechanical, electrical, plumbing (MEP) engineer is an expert that is needed to accurately and efficiently determine the correct commercial kitchen hood ventilation design needed for your kitchen build. Also, collaborating with an MEP engineer will ensure that your kitchen is designed with the adequate needs for your specific setup as each kitchen design varies depending on food preparation needs.

There are numerous safety precautions to be taken when working or maintaining a commercial kitchen. The basic fundamental safety concerns in a kitchen including reducing the occurrence of slip and fall incidents. Assuring that sharp tools and utensils are stored, used and passed properly. In addition to this assuring that the cooking surfaces are continuously monitored and cleaned properly is a huge part of overall kitchen safety.

One of the largest concerns is reducing the occurrence of fires. Many commercial kitchen ventilation systems will build up deposits of creosote and grease inside of their exhaust hoods, ducts, and fans from the cooking that is done in the kitchen. The collection of these contaminants will make the system more likely to combust in the proper conditions.

While there are systems that are built into some commercial kitchen hood ventilation system that helps reduce maintenance, no matter what system will be installed in your commercial kitchen it will always be important to regularly clean your hoods, ducts, and fans. Routine cleaning will also be part of maintaining certain standards for health code inspections.

Every commercial kitchen hood ventilation install is are required to host a suppression system will handle cooking fires and will keep the fire from invading the duct system. In addition to this fire suppression system, there are additional add-ons that can help reduce maintenance and increase overall safety including a hood wash system, grease removal system and combined system. By including these considerations in your design process with an MEP Engineer you will reduce the likelihood of unsafe incidents in your commercial kitchen. You will also have a better idea of exactly what type of safety suppression systems you need based on your unique kitchen design and specifications

While health codes will vary from location to location, the need for commercial kitchen hood ventilation is imperative to maintaining a clean, inhabitable and safe cooking environment. Without a properly installed kitchen ventilation system, your commercial kitchen runs the high likelihood of imparting foodborne illness, or worse yet, unsavory eating conditions in your dining establishment.

The cleanliness of your ventilation system is paramount to its overall functioning and ensuring that it does not run the increased risk of igniting kitchen fires. Without a properly functioning commercial kitchen hood ventilation system, the cooking environment has untenable levels of humidity and will create and maintain an environment that is a breeding ground for mold, bacteria and other foodborne illnesses.

Maintaining Health Codes is one of the ongoing priorities of any kitchen operation. What many kitchen designers and contractors might not understand is that to keep a safe environment in the commercial kitchen it is required that your commercial kitchen hood ventilation be integrated and work in tandem with your restaurants overall HVAC system to have the most effective and efficient functioning.

From the “Chicago Board of Health Rules and Regulations Pertaining to Sanitation Practices in Food Establishments”

Section - Construction and Maintenance of Building Facilities - Part D. Ventilation

The kitchen in all food establishments shall have adequate ventilation, and the air flow shall

always be from the dining room through the kitchen. The flow air discharged from kitchen fans

shall always be through a duct to a point above the roof line. Ranges and fryers shall be hooded

so that the cooking odors may be effectually carried off by a stack, an exhaust fan, or skylight

immediately above. Hoods shall be so designed to prevent grease and condensate from dripping into food or on food preparation areas. Filters, if used, shall be readily removable for cleaning.

As you can see, it is imperative that you have the proper equipment called out on your plans and in your commercial kitchen design.

Penalties for not having a commercial kitchen hood ventilation will vary from location to location and the specific financial and legal penalties will be determined based off of the codes in your specific geographical area.

At the very least it is required by my agencies including Fire Marshals, Health Inspectors, Insurance Companies that all commercial kitchen hood ventilation be cleaned based off the usage. According to The National Fire Protection Code 96, there is a maintenance schedule that must be followed. These national standards are used as a guideline for codes and regulations across the nation.

This examination of commercial kitchen hood ventilation demonstrates the integral nature of assuring that your kitchen design and build position the ventilation as the central focus at all times. As professional engineers, we are familiar with the customization required for each kitchen design and ensure that kitchen safety and maintaining health codes are paramount considerations on this type of project. By partnering with NYE on your design, our expertise serves our clients by saving them the time involved in the necessary completion of these processes while not compromising on the quality of your project.

A qualified MEP engineer can help you choose the correct equipment based on a number of factors. The engineer is required to have a certain level of construction and mechanical, electrical, Plumbing knowledge. they are also required to know and understand the load calculations necessary to size MEP equipment. Their experience and knowledge gives them the basis to effectively and efficiently size your MEP equipment.

A local qualified MEP engineer will have knowledge and understanding of the local building codes and local governing bodies for the commercial construction industry. They are your expert boots on the ground in the mechanical, electrical, plumbing areas of your project. The MEP engineer is a vital component of your construction team and someone who you should use as a reliable resource. If your general contractor does not have an MEP engineer in-house, do your due diligence and find one that you work well with.

The MEP engineer will be able to review the plans you have drafted with your architect and with all of the information you have gathered on the size of equipment you think you need, they won't be able to determine your next steps and the direction you need to go. They may need to conduct additional or complementary research and inquiries to verify they are making the correct recommendation for the type of equipment for your application.

Calling on the experts like an MEP engineer will help your project succeed in the long run and help you to continue being profitable and efficient. Knowing when to call in an expert is a valuable skill to have. If you think you need an MEP engineer please take a moment to contact us and we would be happy to review your project information. We are pleased to serve the Chicago area and welcome local and out of state clients.

382 NE 191st St , Suite 49674

Miami, Florida 33179276 5th Avenue, Suite 704 #904

New York, NY 10001