Our HVAC solutions are designed to ensure optimal comfort, regardless of outdoor temperatures.

We identify & eliminate unnecessary energy consumption, leaving you with maximal functionality for the minimum annual energy cost.

All of our systems are designed with longevity in mind, saving you maintenance costs down the line.

Click to view PDF in detail

Click to view PDF in detail

sub-slab depressurization technology as "a system designed to achieve lower sub-slab air pressure relative to indoor air pressure by use of a fan-powered vent drawing air from beneath the slab." When you are looking at designing and installing a sub-slab depressurization system having a professional involved will help you avoid costly mistakes and project delays. They will be able to see the big picture of the system and the overall design of the building. However, our expert engineers and designers are experienced in the field of MEP, so we can assure to deliver only the top sub-slab depressurization system design based on our clients’ exact specifications.

We are one of the fastest growing MEP design firms in the construction industry. We pride ourselves on having a fast turnaround while providing cost effective solutions. We are licensed in 50 states and are your one stop shop for all MEP design needs.

We are licensed in all 50 states!

We design to the perfection

Enjoy our lightening fast turnaround

We have completed so far!

Our designs are approved by DOB in one go

The best service experience in the market

Every construction project has its own idiosyncrasies and problems that come up. Sometimes these problems don't come up until after the project has long been completed. As the earth settles over time the geotechnical surveys that were completed can become obsolete and won’t always take into account the gases and vapors that are trapped under water-tables and compressed sediment or soil. This eventuality has begun to be more commonplace as structures that were built decades ago are experiencing settling and where new construction was hastily erected.

To combat the rising number of instances and structures where vapor and gas intrusion are happening, new technologies are being developed and implemented to keep the spaces safe. The construction and MEP engineering communities are always working to come up with new and creative ways to mitigate the problems facing building owners and occupants today.

As regulations increase across the country regarding evaluating vapor intrusion pathways, so too is the need for proper mitigation systems. The first step towards properly mitigating vapor intrusion in a commercial building structure involves sub-slab soil gas sampling to identify the levels assess the potential risk.

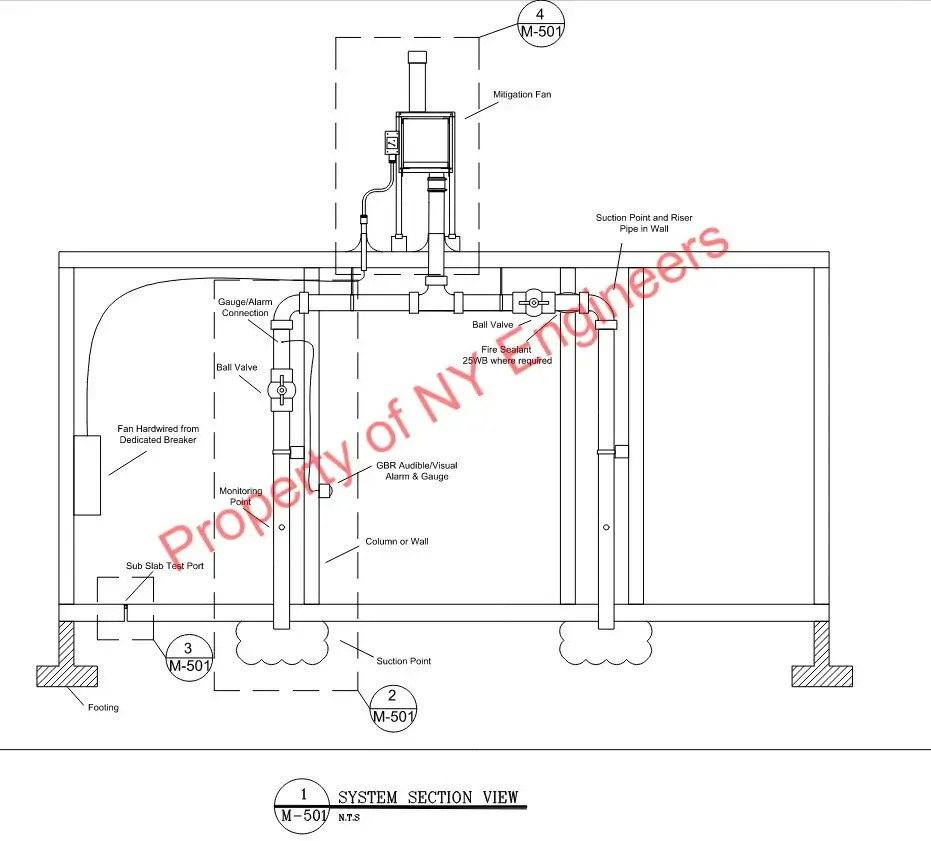

If vapor intrusion is identified, and found to be above the accepted screening levels, a mitigation system should then be designed and put in place. For existing commercial buildings where vapor intrusion is identified, currently the most common mitigation system is the sub-slab depressurization system. These systems are used to mitigate indoor vapors arising from subsurface contamination.

The EPA defines sub-slab depressurization technology as "a system designed to achieve lower sub-slab air pressure relative to indoor air pressure by use of a fan-powered vent drawing air from beneath the slab." Thus, even if there are holes, cracks, or other pathways between the commercial building and the subsurface, the vapors will flow downward, not upward. Therefore, a well-designed sub-slab depressurization system will most likely prevent any toxic vapors from intruding above into the building structure.

These systems usually are designed to capture and take away migrating vapors before they enter indoor air. The vapor originates in contaminated soil or contaminated groundwater found in the water table. The vapor then migrates up through the soil to escape through the cracks, holes, and gaps in our building structures. sub-slab depressurization system allows the intruding vapor to escape through another means and be neutralized before being released into the air.

Most of the sub-slab depressurization systems are designed to remedy issues with existing industrial and residential structures. Recently, there have been additional styles being designed for systems being put in with new structures, that is often a lot of easier than retrofitting an associate existing structure. The number of controls and sensors related to the system is often a mirrored image of the danger related to the migrating vapors for that specific structure. Some larger systems incorporate remote measuring to observe the operation of the vapor mitigation system and to form certain any malfunctions are repaired quickly.

First and foremost ensure that the contractor hired to install the sub-slab depressurization system is certified and has the proper credentials to install the system. Failure to do so can result in an improperly installed system, fines, unsafe work environment, building code violations, and more.

There are a few steps that a certified contractor will take to properly install the sub-slab depressurization system. These steps for the most will remain the same from installation to installation. There may be some variations depending on the environment, building codes, governing body regulations, and a myriad of other as of yet undetermined variables.

In existing structures, installing an SSD system entails cutting one or more holes in the slab, removing a small quantity of soil from beneath the slab to create a "suction pit," and then placing vertical suction pipes into the holes. These pipes are connected to a manifold containing an exhaust fan, and vapors are in turn vented outdoors. Experience has shown that one or two suction pits are adequate to depressurize typical residential homes. A large commercial building needs more.

A sub-slab depressurization system is required when there is vapor intrusion of radon gas. radon gas has been recognized as a potential cancer risk for more than three decades. it can intrude into a structure through the slab of the structure to affect the occupants. In addition, the vapor intrusion of radon gas can come between cracks and holes and gaps within a structure. this includes basements, crawl spaces, and the concrete slab the structure is built on.

We now know that vapor intrusion of radon gas can also happen through a joined attics and walls in commercial and Retail spaces. This is why you will find that there are more sub-slab depressurization systems being included in new construction plans. It is easier to install a sub-slab depressurization system in a new construction project rather than adding one to an existing structure.

Once installation of the sub-slab depressurization system is complete there are certain things that are required on a routine an annual basis to ensure the system is compliant and working correctly. Failure to perform this maintenance and annual inspections can result in unsafe conditions and violations and fees. an example of what an annual inspection might look like is below.

Routine inspections of the SSDS to be completed by the appropriate staff will include:

In addition to the inspection steps mentioned above, it may be required to take certain samples during annual inspections of the system. A sample list of those follows and Is not indicative of what will be required 4 your specific sub-slab depressurization system application. your certified contractor will advise you of what needs to be sampled and measured once your system has been successfully installed.

Sample measurement instructions:

Keeping detailed and accurate records of all maintenance and inspection activity is imperative for the owners to maintain the sub-slab depressurization system. these systems are not to be taken lightly or installed by un-specialized contractors. Be certain that the installation and maintenance post installation is performed by the proper personnel to ensure everyone's safety.

As with any mechanical system designed by people, there are bound to be limitations and weaknesses in the system. The sub-slab depressurization systems are no different. Here are a few things to be aware of when designing and installing SSD systems

This is not an all inclusive list and every effort should be made to consider all of the angles and possibilities when designing and installing an SSD system.

Bringing in an MEP engineer early on in your project means you will have access to a professional who will be able to identify all of the aspects that need to be considered. When you are looking at designing and installing a sub-slab depressurization system having a professional involved will help you avoid costly mistakes and project delays. They will be able to see the big picture of the system and the overall design of the building. This includes how everything works together and how the new installation will affect the loads on the other pieces of your building infrastructure. This will aid them in interfacing with the architect to address any concerns they may have with the plans or existing structure.

A local qualified MEP engineer will have knowledge and understanding of the local building codes and local governing bodies for the commercial construction industry. They are your expert boots on the ground in the mechanical, electrical, plumbing areas of your project. The MEP engineer is a vital component of your construction team and someone who you should use as a reliable resource. If your general contractor does not have an MEP engineer in house, do your due diligence and find one that you work well with.

Calling on the experts like an MEP engineer will help your project succeed in the long run and help you to continue being profitable and efficient. Knowing when to call in an expert is a valuable skill to have. If you think you need an MEP engineer please take a moment to contact us and we would be happy to review your project information. We are pleased to serve the Chicago area and welcome local and out of state clients.

382 NE 191st St , Suite 49674

Miami, Florida 33179276 5th Avenue, Suite 704 #904

New York, NY 10001