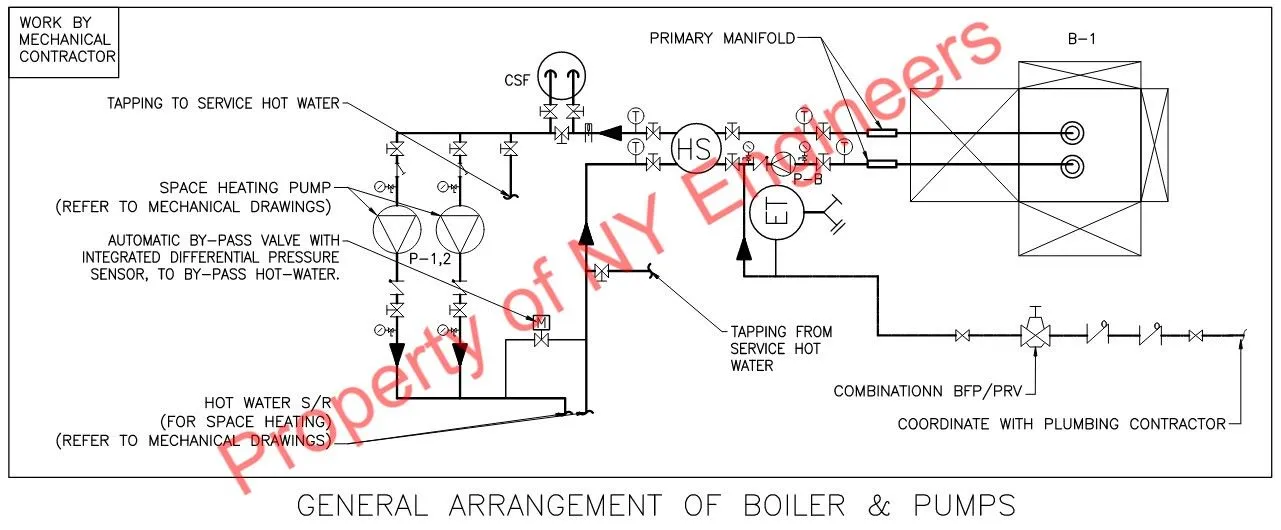

With our design software, we can make the most accurate MEP models for your machines. We ensure that they’ll have all the precise measurements and functions necessary.

We will make sure that your machine will not eat up too much power to run by making it as energy-efficient as possible. That way, you can also save costs in the long run.

With a good design, you won’t have to worry about your machine breaking down often nor will you have to worry about repairs too much. We got this covered.

Click to view PDF in detail

Click to view PDF in detail

Do you use a low pressure steam boiler system for your home or your establishment? If you do, then you’ll probably know about the energy costs that you’ll have to operate the machine plus maintenance. You’ll also have to worry about those times when the machine bucks down and call for repairs.

We understand how much of a hassle these aspects are which is why we at Nearby Engineers New York Engineers have the solution to your woes. With our mechanical, electrical, and plumbing design services, we can create a realistic model of the actual machine. At the conceptualization stage, we can already make your machine flawless so that the end product will also be perfect. Whether you live in or outside of Chicago, you can surely put your trust in our MEP design expertise.

We are one of the fastest growing MEP design firms in the construction industry. We pride ourselves on having a fast turnaround while providing cost effective solutions. We are licensed in 50 states and are your one stop shop for all MEP design needs.

We are licensed in all 50 states!

We design to the perfection

Enjoy our lightening fast turnaround

We have completed so far!

Our designs are approved by DOB in one go

The best service experience in the market

Design is the main foundation of every project. If ever the design is flawed, then your machine will also surely be flawed. With a flawed design, you will be spending thousands of dollars on recalibration, repairs, and maintenance.

If you choose to use an MEP design, you will be able to enjoy the following benefits:

Our special toolkit can give you all of those benefits when you partner with us in creating an MEP design. As long as the backbone is well built, then you can be sure that all the other parts will remain in tiptop shape.

One of the things that make us stand out would be our strict, streamlined process. This allows us to further maximize our productivity and meet deadlines right on the dot. Just to give you an idea, here is how we do things:

As you can see, we are very systematic with our approach to our MEP designs. We believe that a systematic, step-by-step approach such as this will allow us to create your low pressure steam system design flawlessly.

Combined with our systematic approach, we also have a team of expert engineers who have impeccable qualifications when it comes to engineering project designs. These two aspects have allowed our company to cement its reputation as one of the best MEP design firms.

With a high-quality design from our company, you now can avoid having to do manual troubleshooting if ever your machine doesn’t work the way it is supposed to. Having a good design allows you to avoid errors and system flaws for your steam system. You will also not need to do too many repair jobs since we have created the design to be very durable. With that, you can say goodbye to high maintenance machinery and complicated hiccups along the way.

As your partner in building your low pressure steam boiler system, we will ensure that you will get the machine that you’ve always visualized. It all starts with the design.

When we created designs for low pressure steam systems, we are extremely meticulous with detail because these machines are rather sensitive and need to be built with intense precision so that it will last longer and work in the most efficient manner.

In order to create an efficient steam system, we have to make sure that the machine efficiently distributes steam through the pipes. When a low pressure steam system operates, it would heat up water from the boiler, producing steam. The steam then gets pushed through the piping and through a radiator to provide heat to homes or establishments.

So as you can see, there is a certain flow that has to be followed when we design our low pressure steam systems. For the flow to remain smooth, we need to make sure that all parts are in good working condition and are all in sync with each other.

The design of these steam systems can be a little bit complicated, but we can break it down, so it’s simpler to understand. Basically, we take a few things into consideration when we create our MEP designs:

Pressure Design

We always consider the pressure design first before we create our designs. We know for a fact that low pressure steam systems are only limited to 15 PSI. Of course, we also make sure that we customize this based on what our customers need and want. But as a general rule, we keep to 15 PSIG design and nothing higher.

Heating Load

One of the biggest factors that we take into consideration would be the heating load or the size of the machine. When we brainstorm with our clients, we also take into consideration the weather conditions so that we know how much heating load to add. We prefer to be a little flexible with our low pressure steam systems’ design so that the features can match and adapt to the situation of the client.

Heating Capacity

Just like the PSIG design, the heat must also be limited to a minimum in order for the steam to move through the pipes smoothly. As designers, we need to ensure that the machine keeps to only a temperature of below 250 degrees Fahrenheit; otherwise, the machine will border toward the high pressure steam system type and may not take the load.

Local Emission Regulations

We understand that there are certain regulations that need to be observed when designing heavy machinery such as this. That said, the regulations may differ per state. For instance, machine regulations in Chicago may be different from that in other states. With that, Nearby Engineers New York Engineers will always discuss local machinery regulations with our clients before tackling the design so that we follow the policies of each state.

Piping System

Lastly, we will consider the piping system that can be installed in the area of our client. When we create our design, we need to make sure that the machine fits right into the area which is why we send principals to do thorough inspection first. We can take a look at the existing piping system or the area where can install extra pipings.

While we are pretty specific when it comes to what we consider in building your low pressure steam system MEP design, we are also rather flexible with regard to customizations so that we can tailor-fit the final design to what you need.

382 NE 191st St , Suite 49674

Miami, Florida 33179276 5th Avenue, Suite 704 #904

New York, NY 10001